Copper Rod Continuous Casting and Rolling Line

Product Details

1. Prospect

Under the situation of scarce copper resources and increasing stringent environmental protection requirements, most countries recycle and reuse scrap copper to save copper resources and protect the global environment.

Most countries in the world are no longer adopt traditional boat-shaped copper ingots, but instead adopt continuous casting and rolling (CCR) production processes.

Scrap copper is melted into recycled copper ingots through slag removal and crushing. Copper ingots are then processed to produce various copper products which meet the requirements. The continuous casting and rolling process can directly produce bright and low-oxygen copper rods that meet the requirements of wire and cable. Compared with copper ingot recycling, the direct recovery and reuse of copper scrap not only reduces the processing steps and improves the recovery rate of copper scrap, but also reduces the production cost by about 5%.

The continuous casting and rolling production line provided by us can use scrap copper as raw material and packed it into copper ingots through a hydraulic baler, the copper ingots are refined into liquid copper by REDOX in a reverberatory furnace. The liquid copper is produced into copper ingot through the launder, pouring it in continuous casting machine. And then the copper slab is rolled and sheared, straightened and scraped, and roughened into a hot continuous rolling mill to be rolled into a bright and low-oxygen copper rod.

This technology cleverly combines the two processes of casting and rolling. Compared with the traditional process that casting copper slabs first and then heating them in a heating furnace and rolling, it has advantages of simplifying the process, improving the working conditions, increasing the metal yield, saving energy, improving the quality of continuous casting ingot, and facilitating the realization of mechanization and automation.

In the 21st century, the wire and cable industry has developed rapidly around the world. In China, copper for the wire and cable industry is growing at an annual rate of about 10%. With the increase of the demand for wire and cable, the demand for raw materials for copper rods will increase. Continuous casting and rolling, the main manufacturing method of copper rods, will surely be more widely used in the future. Recycling copper rods from scrap copper will also usher in the spring of industry development.

We makes technological innovation on the basis of fully absorbing and digesting advanced production technology of similar international equipment from United States, Germany, Italy, etc. Our equipment has characteristics of simple structure, convenient operation, high production efficiency, high yield, low failure rate, low energy consumption, excellent copper rod quality and so on.

2. Production Process

Scrap Copper →Melting and Refining in Reverberatory Furnace → Launder to Protect Molten Copper → Ladle →Casting Machine →Haul Device → Roller Shears → Straightener →Burr Shaver → Feeding Device → Rolling Mill →Cooling and Deoxidizing Device for Copper Rod →After Haul Device → Coiler to Lay Rod into Coil.

3. Technical Parameters

|

Raw Material |

Cathode copper or 100% scrap copper |

|

Furnace |

Cathode copper: Shaft furnace+Holding furnace |

|

100% Scrap copper: Reverberatory furnace |

|

|

Productivity(T/h) |

5-16 |

|

Casting Bar(mm²) |

1400-2330 |

|

Coil’s Weight(kg) |

3000-5000 |

For more information on different configurations and capacities, please click: Copper Rod Production Lines

4. Finished Copper Rod

By adopting advanced refining technology, this line rolls the refined low-oxygen copper rods produced by the rolling machine continuously to produce Φ8mm bright and low-oxygen copper rods. The copper rods can meet the requirements of Chinese GB / T3952 standard and relevant international standards.

The finished copper rod is as follows:

5. Professional Technical Team

We can provide our customers with the most professional and comprehensive technical support with rich experience and a professional technical team.

In addition to providing customers with a full set of detailed drawings, technical documents and other information, we also provide a professional technical team to the customer site for installation and commissioning, and provide customers with face-to-face technical guidance.

Scrap copper recycling, casting and rolling line requires not only a professional continuous casting and rolling production line, but also a mature production process. Because the difficulty and key point of scrap copper recycling, casting and rolling line lies in the production process. Only a complete and mature production process can produce the low-oxygen copper rods that meet the standard requirements with bright appearance and stable diameter. Our technical team can provide two to three years of on-site technical guidance in the customer's factory until our customers have mastered a professional level of copper rod continuous casting and rolling production process.

Choosing our equipment means choosing a strong and professional technical team and first-class quality and perfect after-sale guarantee.

Your choice is the beginning of our cooperation.

6. Our Markets

At present, the copper rod continuous casting and rolling line business activities have cooperated with more than 20 countries including the United States, Canada, South Africa, Iran, Vietnam, Thailand, Japan, Turkey, Russia, Ukraine, Indonesia, Pakistan, Brazil, Malaysia and other countries.Cooperating clients include MIM COPPER, BRASCOPPER, DALONG, etc.

Main Componets

1. Reverberatory Furnace

Waste copper rectangular fixed-type reverberatory furnace is a special smelting equipment that uses liquefied petroleum gas, heavy oil or natural gas as fuel and scrap copper as raw material to complete melting, oxidation (slagging), reduction and other smelting processes.

The reverberatory furnace is mainly composed of steel structure, refractory material, furnace door and transmission equipment, gas burner, air supply system and electronic control system.

The reverberatory furnace provided by us has advantages of simple structure, good adaptability to raw materials and fuels, long furnace life, convenient operation, easy control, high operation rate, suitable for large, medium and small scale production, and less water consumption in production and so on.

According to customer requirements, the capacity of the reverberatory furnace can be designed such as 40t, 60t, 100t, etc.

2. Wheel Casting Machine

The liquid copper which are refined by the reverberatory furnace cast in the crystal wheel cavity of the casting machine through launder and pouring pot. After water cooling, the liquid copper will rapidly condensed and solidified into the casting rod ingot.

The wheel casting machine is mainly composed of driving mechanism(body), crystallization wheel, compaction wheel, tensioner, pouring pot device, cooling device, drying device, ingot puller, lead bridge, carbon coating device, flow control device, and air-drying device, etc.

The crystallization wheel provided by us uses copper-chromium-zirconium. This crystallization wheel has advantages of high hardness, wear resistance, antiknock, good cracking resistance, high production efficiency, long service life, and long-term continuous production.

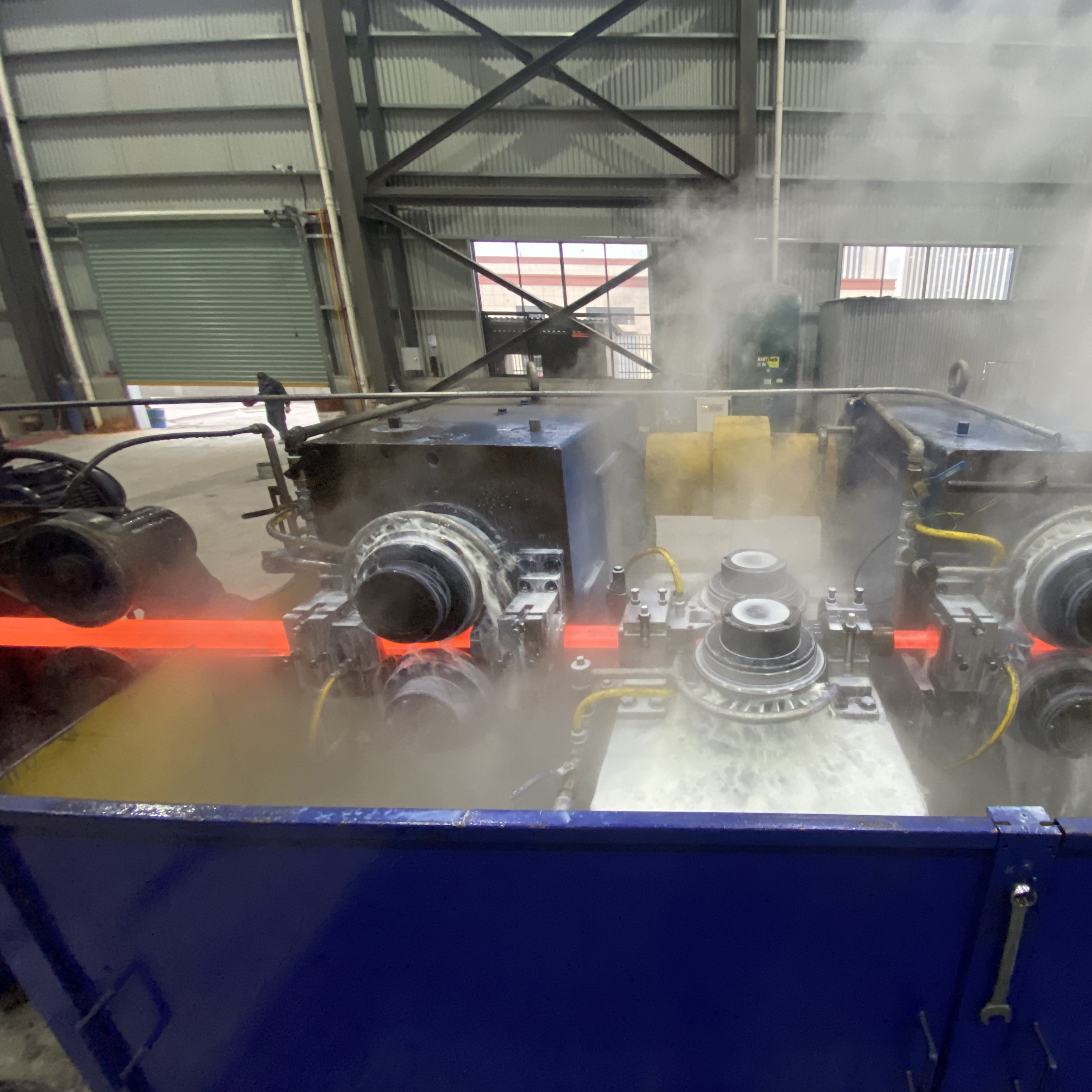

3. Continuous Rolling Mill

Continuous rolling of copper rod ingots manufactured by the casting machine.

The rolling mill provided by us adopts active feeding, the final rolling speed can reach (8.1~9.9) m/s, and the outer diameter of rod is 8mm. It has advantages of convenient operation, easy control, high production efficiency, stable rod diameter, bright copper rod, etc.

Commercial Parts

Raw Materials

The copper continuous casting and rolling production line provided by us can use scrap copper as raw material for copper rod production.

Scrap copper of grade 1 or above grade 2 are used in a certain proportion.

Among them: Scrap copper of grade 1 should be clean and non-alloy copper wires free from tin, containing no fragile burned wires which including bare, uncoated, alloy-free copper wire with no oxidation on the surface and no wool. The diameter of the copper wire is not less than 1.6mm.

Scrap copper of grade 2 should be small diameter non-insulated copper wires, usually containing telephone wires, copper strip with varnish or paper insulation, and thick or thin clean copper bar, also including clean, colorless, uncoated, tin-free, alloy-free copper wires and cables, free of wool and burnt brittle copper wires.

Auxiliary Equipment

Scrap Copper Baler

Scrap copper needs to be packed into copper blocks by scrap copper baler before casting. The scrap copper baler is shown below:

The scrap copper baler adopts hydraulically driven, and has characteristics of simple structure, durable, convenient operation, fast packing speed, compact packing block and so on. The scrap copper can be extruded into various shapes such as cubes, cylinders, etc., which can not only reduce transportation and smelting costs, but also improve the speed of furnace operation. The packed copper block is shown below:

Installation and Commissioning

1. 14 days before the inspection before delivery at Manufacturer’s plant, the Buyer shall inform the plan schedule of installation, commissioning and test production to the Seller. The both parties will finalize this plan during the period of inspection visit.

2. All the civil work should be done by the customer according to the drawings from manufacturer. The buyer should prepare all raw materials, auxiliary materials, production tools, production workers and etc

3. Commissioning (checking the wire and cable connections, water supply, air supply, etc. and make corrections), adjustment of the equipment and start-up of test run.

4. For the installation/commissioning and test production, for specialist needed, time needed, allowance, please check following table:

|

Time |

1-15D |

16-30D |

31-45D |

46-50D |

61-75D |

76-90D |

|

*F-A |

||||||

|

F-B |

||||||

|

CCR-C |

||||||

|

CCR-D |

||||||

|

*P-E |

||||||

|

P-F |

||||||

|

P-G |

*F means furnace; *P means process.

**Furnace building; Furnace heating; CCR installation; Commissioning.

* Remark: The schedule is for a reference. The real time needed is according to the site.

FAQ

Q: Can I visit your factory?

A: All the customers from both home and abroad are warmly welcomed to visit our company and factory.

Q: Do you supply the installation and commissioning?

A: Yes, we do as followings:

-As soon as customer informed us the machines are put in the right place, we will send both mechanical and electrical engineer for machine start up.

-No-load testing: After machine installed completely, we make no-load testing first.

-With-load testing: Usually we will can produce 3 different wires to make load testing.

-Acceptance report: After the buyer confirms that machine can reach all specification under contract, the acceptance report will be signed for our record that machine will be in guarantee period.

Q: What information should I offer to get a detailed quotation from you?

A: For single machine: Usually we need to know inlet wire size, outlet wire size to be produced, productivity, pay off and take up size to choose the right machine.

For new cable plant or new cable production line, we need to know the datasheet of cables to be produced, the productivity, the standards to be followed, etc to design all machines needed.

Q: Can you supply the auxiliary equipment along with the machines?

A: Yes, definitely.

We has supplied heat exchanger, copper/aluminum powder filter machine, cooling tower, chiller, air compressor, drawing dies, pointing machine, cold welders, bobbins etc. with our machines.

Q: Could you do the design for the whole plant?

A: Yes, this is our advantage.

With the data sheet of cable to be produced, the standard your cables should follows, the productivity you expected. Our engineer on production technology and machinery will make design of production machines, test equipment, accessories like bobbins, dies, rewinding lines and materials needed.

Q: How can I know the status of my order?

A: We have our OA system on tracking the production.

For any of your request we can send photos and videos of your order, also we can use FACETIME to let you know the production.

Q: How do you work on the inspection before delivery?

A: We will make dynamic balance testing, levelness testing, noise testing, etc. during production.

After production finished, usually we make no-load running of each machine before delivery. Customers are welcomed to attend the inspection.

Q: What exhibitions will you attend, can we meet in the fair?

A: Dusseldorf International Wire and Cable Fair;

Wire South America Fair;

International Wire and Cable Fair in Shanghai;

International Istanbul Wire Fair, etc.

wire Southeast Asia Fair, etc.