Automatic Cable Coiling And Strapping Machine - China Manufacturers, Factory, Suppliers

Our goods are commonly recognized and reliable by consumers and may satisfy continually developing economic and social needs for Automatic Cable Coiling And Strapping Machine, Copper Cast, Bow Type Laying Up Machine, Wire Scrap Machine,Cable Coiling Machine. It can be our wonderful honor to meet your requires.We sincerely hope we can cooperate along with you inside the around long term. The product will supply to all over the world, such as Europe, America, Australia,Israel, US,kazakhstan, Riyadh.We supply professional service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound products with good logistics service and economical cost. Depending on this, our products are sold very well in the countries in Africa, the Mid-East and Southeast Asia.

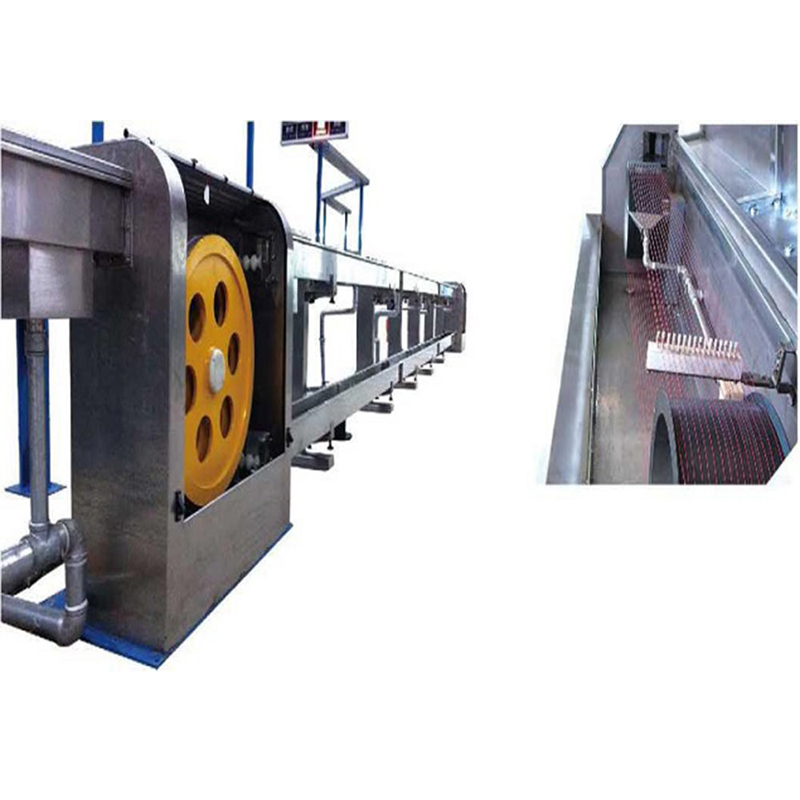

Related Products