Cable Bunching Machine - China Manufacturers, Factory, Suppliers

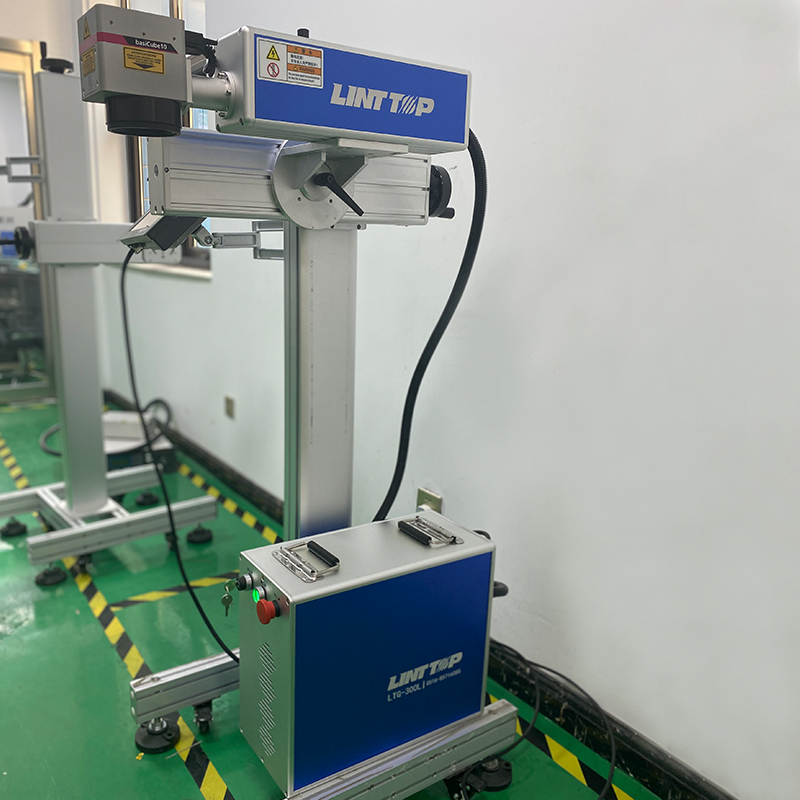

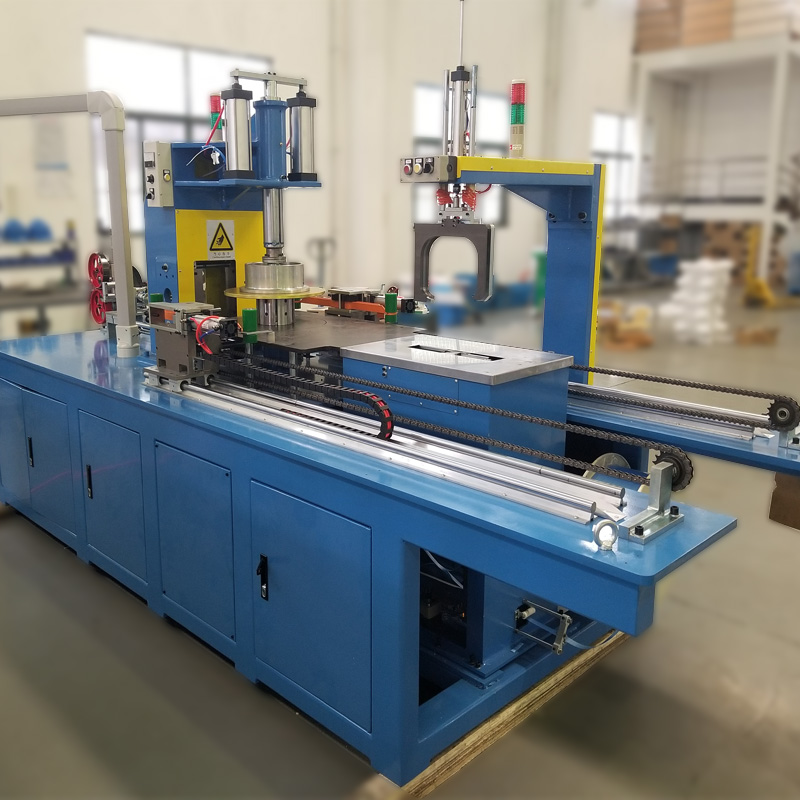

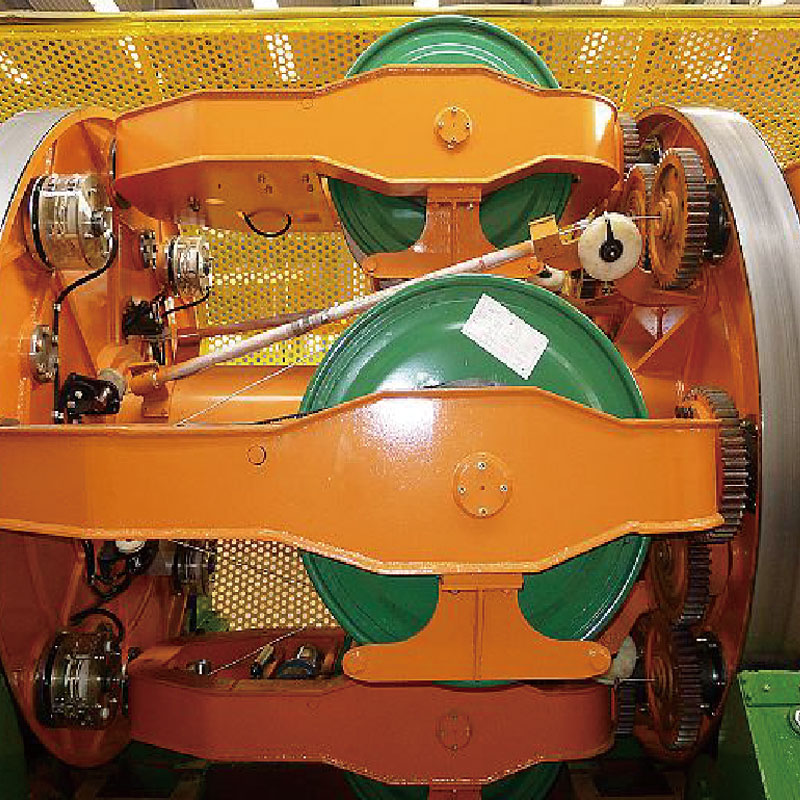

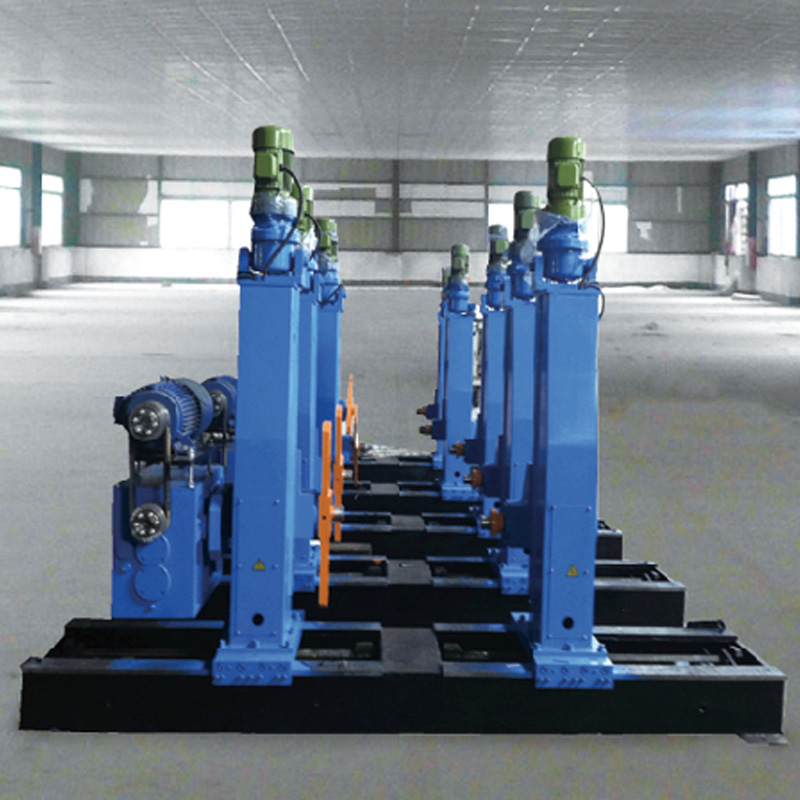

We constantly continually give you essentially the most conscientious client provider, plus the widest variety of designs and styles with finest materials. These initiatives include the availability of customized designs with speed and dispatch for Cable Bunching Machine, Cable Shredder Machine, Cable Granulator, Copper Drawing Machine,Wire And Cable Laser Printer. We warmly welcome all interested customers to contact us for more information. The product will supply to all over the world, such as Europe, America, Australia,Bulgaria, Paris,Angola, Myanmar.We have more than 100 works in the plant, and we also have a 15 guys work team to service our customers for before and after sales. Good quality is the key factor for the company to stand out from other competitors. Seeing is Believing, want more information? Just trial on its products!

Related Products