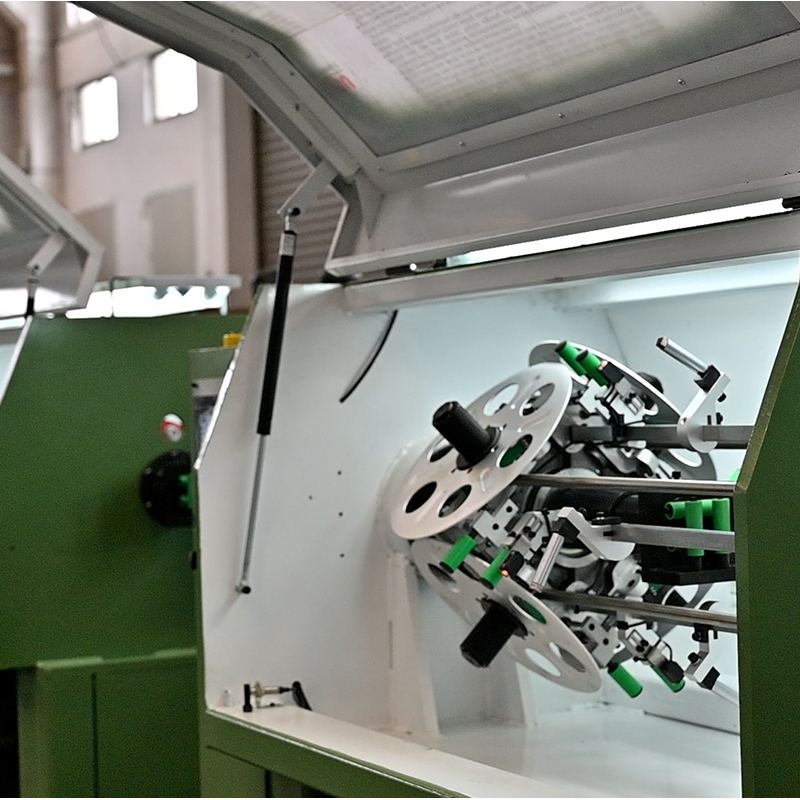

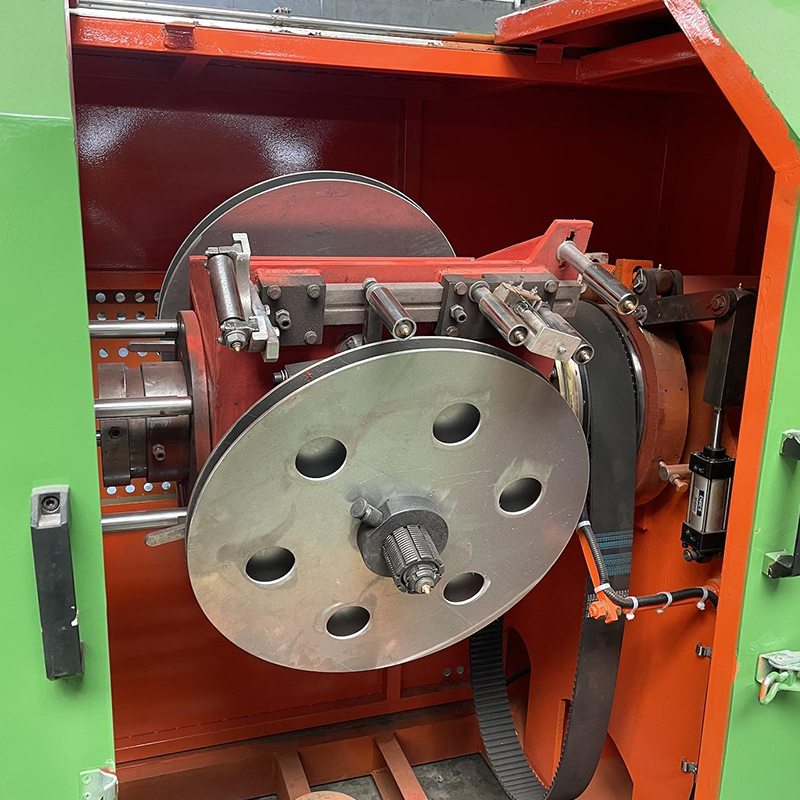

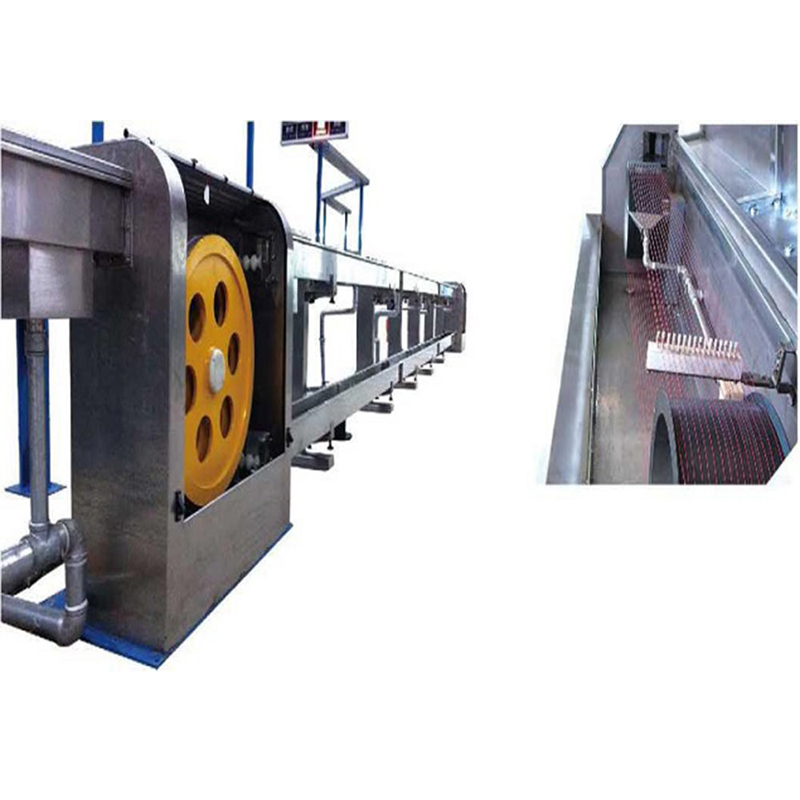

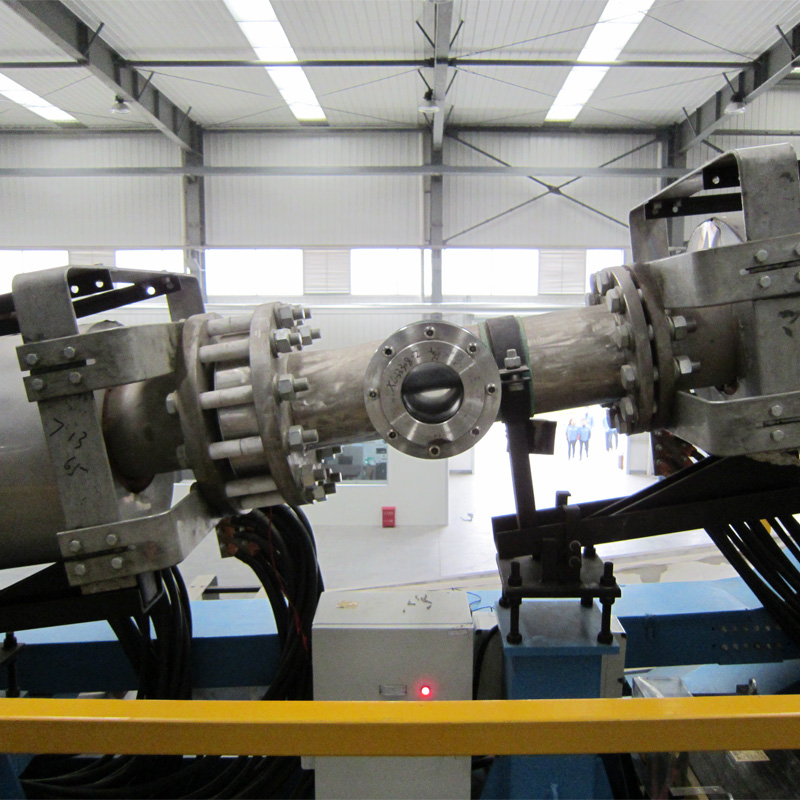

Cable Wrapping Machine - Factory, Suppliers, Manufacturers from China

Persisting in "High quality, Prompt Delivery, Aggressive Price", now we have established long-term cooperation with consumers from equally overseas and domestically and get new and old clients' large comments for Cable Wrapping Machine, Cable Cold Welder, Winding Wire Cable Machine, Spooling Machine,Breakdown Cable. We are able to do your tailored get to fulfill your own satisfactory! Our organization sets up several departments, including manufacturing department, sales department, high quality control department and sevice center, etc. The product will supply to all over the world, such as Europe, America, Australia,Slovak Republic, luzern,Algeria, New Zealand.We believe in quality and customer satisfaction achieved by a team of highly dedicated individuals. The team of our company with the use of cutting-edge technologies delivers impeccable quality products supremely adored and appreciated by our customers worldwide.

Related Products