Metal Sheathing Line Argon Arc Welding, Molding and Corrugating

Product Details

To meet the needs of economic development, the power supply system is developing towards higher and higher voltage levels. In the power supply system, ultra-high-voltage power cables play a role in power transmission. These types of cables generally require a metal sheath structure to meet the performance requirements of the cable itself and the requirements of the environment.

At present, metal sheath of ultra-high voltage power cables is generally protected by inert gas (helium or argon), after the aluminum tape (stainless steel tape) is finely cut, the longitudinal seam is formed by a special mold and then the longitudinal seam is welded. Finally, it is produced by stretching, sizing and crimping. LT-HG200 argon arc welding, molding and corrugating production line provided by our company is a special equipment for manufacturing high-performance ultra-high voltage power cable metal sheath.

The technical difficulty is welding process, but we have rich experience in this field. By drawing on the technical characteristics of the European welding production line, taking advantage of the shortcomings, continuous technological innovation, the reliability, stability and convenient operation of the equipment welding have become the domestic leading level, which can be comparable to European equipment.

1. Features

1. Easy to operate. The welding torch can meet the arbitrary adjustment of the three axis directions of X, Y, and Z, with the welding gun rapid turning device, and the welding gun automatic tracking system to ensure that the welding pin is always directly above the welding seam.

2. Stable operation. Specially designed forming tool and multi-channel horn die gradual forming to ensure stable welding.

3. Humanized design. The production line can roll ring patterns and spiral patterns, patterns of rolling can be concentric or eccentric. The depth and pitch of corrugating can be adjusted online.

2. Main Technical Parameters

|

Welding Tube Outside Dia. (mm) |

Ф60-Ф200 |

|

Welding Metal's Thickness (mm) |

Aluminum:0.8-4.0 Copper: 0.3-1.5 Stainless steel: 0.3-1.0 |

|

Welding Speed |

0-4.6m/min, continuous adjustable |

|

Corrugation Type |

Helical or annular |

|

Corrugation Thread Pitch (mm) |

10-50 |

|

Corrugation Depth (mm) |

1.0-8.0 |

|

Protect Gas |

Argon, Helium (For aluminum) |

The equipment adopts specially designed forming tools and crimping machines, so that it has excellent cable manufacturing stability and is the first choice for the manufacture of ultra-high voltage power cable metal sheaths.

3. Production Process

Cable pay off→Core kickstand→Metal tape pay-off→Strip edge trimmer→Scrap take-up→ Precision longitudinal wrapping→Argon arc longitudinal butt welding→Arc monitoring→Stretch sizing→Caterpillar capstan→Corrugating machine→Take-up

4. Corrugating Effect

In addition, the equipment also can weld and corrugate copper tapes according to different product needs.

Main Components

The equipment is mainly composed of cable core pay-off stand, cable core pay off bracket, Tape pay-off, welding platform, tape feed positioning device, precision cutter device, tape discharge positioning device, waste edge receiving device, precision molding device, welding mold frame, welding gun adjustment device, welding machine, gas supplier, diameter die fixed, welding cooling device, caterpillar capstan, corrugating machine, take-up and traverser, arc monitoring system, electrical control system, etc.

1. Precision Cutter

The device is vertical roll cutting, consists of two cutters and two sleeves. It is used to continuously cut metal strip to the required width for welding round tube. The left and right knife sets are based on the positioning of the vertical plane of the production line and the guide key way, and the width of the cutting band is adjusted by the precise positive and negative threads at the same time; the upper and lower knife sets are based on the lower knife set, and the upper knife set can be along the X and Z axes. Finely adjust the feed amount and knife gap to ensure that the cutting belt is smooth and uniform without burrs.

The cutter material is high-speed tool steel. When the cutter has been used for a long time, the blade will be blunt, remove the blade, just sharpen it with a surface grinder, reinstall it, and adjust the side clearance between the blades with the dial.

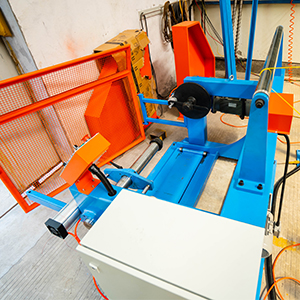

2. Corrugating Machine

It is used to roll corrugation on the drawn metal pipe. The corrugating machine adopts a special spindle structure, which has good rotation accuracy and sufficient support stiffness to ensure the surface quality of the metal sheath after corrugating; the corrugating and traction are mechanically synchronized, the corrugating pitch is stable and the depth can be adjusted online and display in time, easy to adjust.

The corrugating can perform concentric or eccentric, the pitch and depth can be adjusted; it has two functions of producing ring patterns and spiral patterns. The corrugating die is rolled on metal tube instead of purely sliding, so the wear is small, and the operating life can be long.

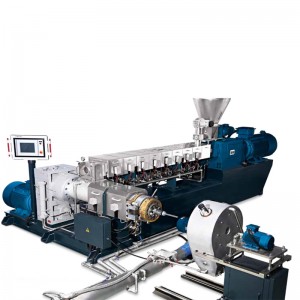

3. Welding Machine

The welding machine is imported from Germany. DC welding power supply, with automatic forced air cooling, with main parameter display; welding current is stable and continuously adjustable, which can meet the stable welding function of large current. The success rate of arc starting is over 98%.

4. Metal Tape Connector

LT-JD600 argon arc welding tape connector can be used for horizontal joint welding of the metal sheath of the ultra-high voltage power cable. It is used to cut the two ends of the two clean metal tape accurately. After the opposite ends are cut through the transverse cuts, continuous butt joint welding is performed under the protection of inert gas, and the two metal strips are connected horizontally to ensure the continuous production.

The equipment is mainly composed of a belt cutting unit, a fixed tooling unit with a head, a walking transmission unit for a welding gun, a movable working platform, an electronic control system, etc. The width of tape can be up to (200~700) mm, the thickness of tape can be up to aluminum tape (0.80~4.0) mm, copper tape (0.30~1.5) mm, and steel tape (0.30~1.0) mm. The welding speed can be continuously adjusted within (0~1.40) m / min.

LT-JD600 type argon arc welding tape connector has characteristics of flat metal notch, firm welding and convenient operation. In addition, our company can also provide other models of argon arc welding tape connectors according to customer requirements to meet the different needs.

Auxiliary Equipment

In order to ensure the reliability of cable metal sheath production, corresponding auxiliary equipment is needed to ensure the reliable, stable and efficient production of the entire cable metal sheath. Among them, the eddy current flaw detector is one of the very important auxiliary equipment.

The eddy current flaw detector can detect the weld seam of welded pipes of different specifications and materials on-line, and can effectively identify the defects of welded pipe cracking, under-welding and cracks. The device is controlled by computer, man-machine interface, display working status, and the maximum flaw detection speed can reach 10m / s. In addition, the device can also replace the hydraulic test of the metal sheath to mark the defective area.

The eddy current flaw detector from us has the characteristics of fast detection speed, high sensitivity, strong anti-interference ability, stable performance, low cost, etc. It is especially suitable for online eddy current flaw detection on ultra-high voltage power cable metal sheath production line.

Installation and Commissioning

After the order is established, we will provide customers with foundation drawing and layout drawing. Customers can build and lay foundations according to the drawings we sent.

We will discuss in detail with our customers about the commissioning plan before the equipment arrives at the factory. Customers need to prepare materials for installation and commissioning. Of course we will send a detailed preparation list to help our customers.

We will send two experienced engineers to guide the installation and commissioning, and during the commissioning, our engineers will provide detailed training to the customer’s workers, as well as the problems and solutions encountered during the operation of the equipment.

FAQ

Q: Can I visit your factory?

A: All the customers from both home and abroad are warmly welcomed to visit our company and factory.

Q: Do you supply the installation and commissioning?

A: Yes, we do as followings:

-As soon as customer informed us the machines are put in the right place, we will send both mechanical and electrical engineer for machine start up.

-No-load testing: After machine installed completely, we make no-load testing first.

-With-load testing: Usually we will can produce 3 different wires to make load testing.

-Acceptance report: After the buyer confirms that machine can reach all specification under contract, the acceptance report will be signed for our record that machine will be in guarantee period.

Q: What information should I offer to get a detailed quotation from you?

A: For single machine: Usually we need to know inlet wire size, outlet wire size to be produced, productivity, pay off and take up size to choose the right machine.

For new cable plant or new cable production line, we need to know the datasheet of cables to be produced, the productivity, the standards to be followed, etc to design all machines needed.

Q: Can you supply the auxiliary equipment along with the machines?

A: Yes, definitely.

We has supplied heat exchanger, copper/aluminum powder filter machine, cooling tower, chiller, air compressor, drawing dies, pointing machine, cold welders, bobbins etc. with our machines.

Q: Could you do the design for the whole plant?

A: Yes, this is our advantage.

With the data sheet of cable to be produced, the standard your cables should follows, the productivity you expected. Our engineer on production technology and machinery will make design of production machines, test equipment, accessories like bobbins, dies, rewinding lines and materials needed.

Q: How can I know the status of my order?

A: We have our OA system on tracking the production.

For any of your request we can send photos and videos of your order, also we can use FACETIME to let you know the production.

Q: How do you work on the inspection before delivery?

A: We will make dynamic balance testing, levelness testing, noise testing, etc. during production.

After production finished, usually we make no-load running of each machine before delivery. Customers are welcomed to attend the inspection.

Q: What exhibitions will you attend, can we meet in the fair?

A: Dusseldorf International Wire and Cable Fair;

Wire South America Fair;

International Wire and Cable Fair in Shanghai;

International Istanbul Wire Fair, etc.

wire Southeast Asia Fair, etc.