Professional Design Braiding Machine - Optical Fiber Coloring and Rewinding Line – LINT TOP

Product Details

Professional Design Braiding Machine - Optical Fiber Coloring and Rewinding Line – LINT TOP Detail:

1. Introduction

With the rapid development of optical communication technology, the amount of fiber optic cables used in optical communication systems has also increased rapidly. After drawing the optical fiber, in order to facilitate the identification of multiple optical fibers in the beam tube during subsequent processing and use, the method of coloring on the surface of the optical fiber is generally used. The fiber coloring and rewinding line is a production device that colors the surface of the optical fiber. It can also be used for fiber rewinding.

We have many years of experience in research and development and manufacturing of optical fiber and cable production equipment. The optical fiber coloring and rewinding machine provided by us uses the internationally advanced Japanese Panasonic AC servo drive system, with the advantages of high control accuracy, low noise, high efficiency and reliable operation; And adopt the programmable controller of German Siemens company to control it centrally, so that the control of the whole electric control system is more stable and more reliable. The touch screen adopts a set of control technology, man-machine interface technology, graphics technology, database technology, and network technology, including dynamic display, alarm, trend, control strategy, control network communication and other components, providing a friendly user interface to make the device more intuitive and easier. At the same time, it has the functions of automatic alarm and shutdown when all parts of the pay-off, tension control, UV curing furnace, and take-up and traverser fail, and the speed-up and speed-down procedures ensure that all motors operate strictly in proportion to ensure stable and reliable operation of the entire system without damaging the optical fiber.

We can provide LT05 and LT07 and other models of fiber coloring rewinding machines. Among them, LT07 can be made into single-line or double-line structure according to customer requirements. When the double-line structure is adopted, the coloring and rewinding of two optical fibers can be performed simultaneously, and the production efficiency is twice that of the single-line structure.

2. Main Technical Parameters

|

Model |

LT05 |

LT07 |

|

Number of optical fibers |

1 |

1 or 2 |

|

Structure speed(m/min) |

1800 |

3000 |

|

Coloring speed(m/min) |

≤1600 |

≤2500 |

|

Rewinding speed(m/min) |

≤1600 |

≤2500 |

|

Payoff tension(N) |

(0.3~1.5)±0.05 |

(0.3~1.5)±0.05 |

|

Take-up tension(N) |

(0.3~1.5)±0.05 |

(0.3~1.5)±0.05 |

|

Traversing pitch(mm) |

(0.1~1.0)±0.01 |

(0.1~1.0)±0.01 |

|

Thickness coloring layer(μm) |

3~5 |

3~5 |

|

Additional loss after coloring(dB/km) |

≤0.02 |

≤0.02 |

|

Bobbin size |

Ф236×Ф160×108 (Corning 25km bobbin) Ф236×Ф160×225 (Corning 50km bobbin) |

Ф236×Ф160×108 (Corning 25km bobbin) Ф236×Ф160×225 (Corning 50km bobbin) |

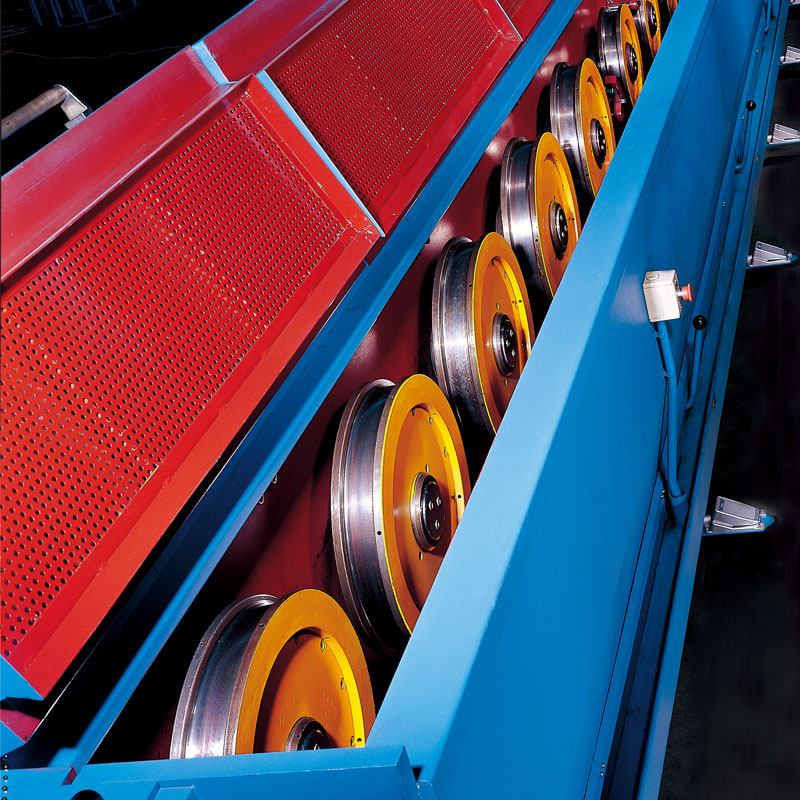

Product detail pictures:

Related Product Guide:

"Control the quality by the details, show the power by quality". Our enterprise has strived to establish a remarkably efficient and stable team team and explored an effective excellent control system for Professional Design Braiding Machine - Optical Fiber Coloring and Rewinding Line – LINT TOP , The product will supply to all over the world, such as: Russia, Latvia, Ukraine, we have complete material production line, assembling line , quality control system, and the most importantly, we have many patents technology and experienced technical&production team, professional sales service team. With all those advantages, we are going to create"the reputable international brand of nylon monofilaments", and spreading our products to every corner of the world. We are keep moving and try our best to serve our customers.

FAQ

Q: Can I visit your factory?

A: All the customers from both home and abroad are warmly welcomed to visit our company and factory.

Q: Do you supply the installation and commissioning?

A: Yes, we do as followings:

-As soon as customer informed us the machines are put in the right place, we will send both mechanical and electrical engineer for machine start up.

-No-load testing: After machine installed completely, we make no-load testing first.

-With-load testing: Usually we will can produce 3 different wires to make load testing.

-Acceptance report: After the buyer confirms that machine can reach all specification under contract, the acceptance report will be signed for our record that machine will be in guarantee period.

Q: What information should I offer to get a detailed quotation from you?

A: For single machine: Usually we need to know inlet wire size, outlet wire size to be produced, productivity, pay off and take up size to choose the right machine.

For new cable plant or new cable production line, we need to know the datasheet of cables to be produced, the productivity, the standards to be followed, etc to design all machines needed.

Q: Can you supply the auxiliary equipment along with the machines?

A: Yes, definitely.

We has supplied heat exchanger, copper/aluminum powder filter machine, cooling tower, chiller, air compressor, drawing dies, pointing machine, cold welders, bobbins etc. with our machines.

Q: Could you do the design for the whole plant?

A: Yes, this is our advantage.

With the data sheet of cable to be produced, the standard your cables should follows, the productivity you expected. Our engineer on production technology and machinery will make design of production machines, test equipment, accessories like bobbins, dies, rewinding lines and materials needed.

Q: How can I know the status of my order?

A: We have our OA system on tracking the production.

For any of your request we can send photos and videos of your order, also we can use FACETIME to let you know the production.

Q: How do you work on the inspection before delivery?

A: We will make dynamic balance testing, levelness testing, noise testing, etc. during production.

After production finished, usually we make no-load running of each machine before delivery. Customers are welcomed to attend the inspection.

Q: What exhibitions will you attend, can we meet in the fair?

A: Dusseldorf International Wire and Cable Fair;

Wire South America Fair;

International Wire and Cable Fair in Shanghai;

International Istanbul Wire Fair, etc.

wire Southeast Asia Fair, etc.