rewinding machine - Factory, Suppliers, Manufacturers from China

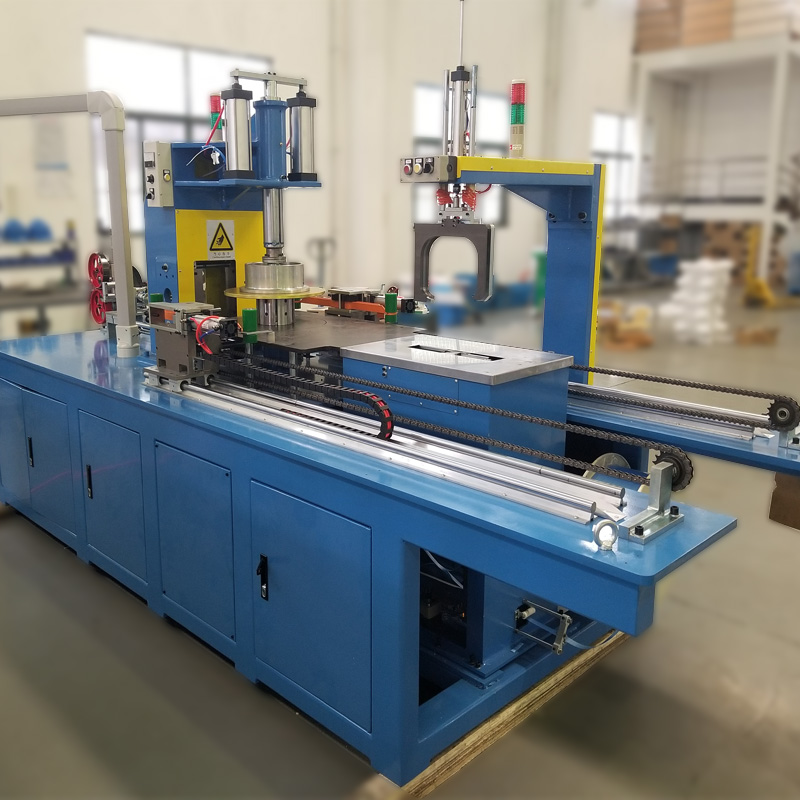

Assume full duty to satisfy all demands of our clients; reach steady advancements by marketing the development of our purchasers; grow to be the final permanent cooperative partner of clientele and maximize the interests of customers for rewinding machine, Extrusion Machines, Planetary Machine, Dual Reel Auto Take Up,Wire Extrusion. Sincerely hope we are growing up together with our customers all over the world. The product will supply to all over the world, such as Europe, America, Australia,Mecca, Malta,European, Pakistan.We follow superior mechanism to process these products that ensure optimum durability and reliability of the products. We follow latest effective washing and straightening processes that allow us to offer unmatched quality of products for our clients. We continually strive for perfection and all our efforts are directed towards attaining complete client satisfaction.

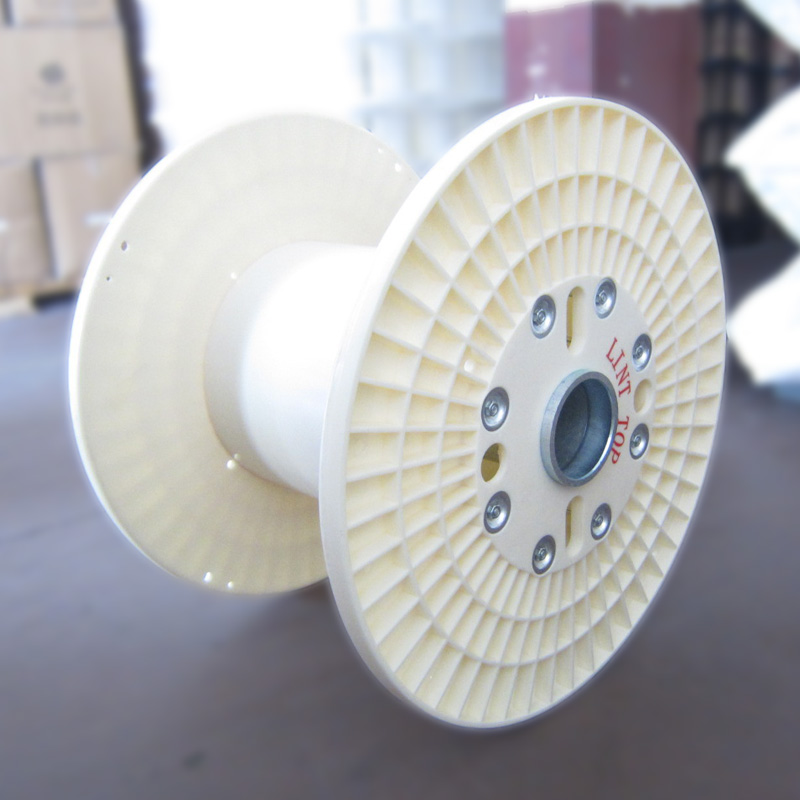

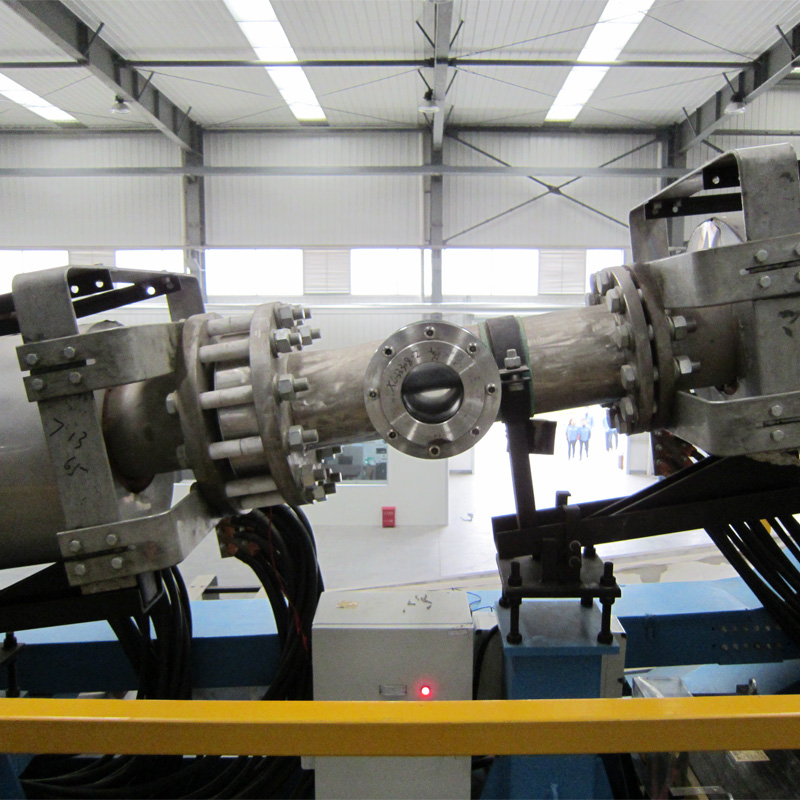

Related Products