Sheathing Extrusion Line

Product Details

1. Introduction

The sheathing is the last production process of the data cable, which directly affects the appearance of the finished cables and directly determines whether the product has a "good look". In the manufacturing process of the sheath, it is not only a matter of the appearance quality, but also related to the electrical performance of the finished cable.

LINT TOP has many years of experience in R&D and manufacturing of data cable production equipment. The sheath production line provided by LINT TOP is suitable for the production of various types of data cable sheaths, and can extrude PVC, PE, LSZH/HFFR and other sheath materials. The production line has the characteristics of uniform extrusion outer diameter, smooth appearance, fast production speed, high production efficiency, precise tension of take-up and pay-off, and convenient operation, etc. It is a professional sheath production line for data cable.

2. Technical Parameters

|

Model |

SJ65/25 |

|

Applicable extrusion material |

PVC, PE, LSZH/HFFR |

|

Production speed(m/min) |

Structure speed: max.150 |

|

Actual speed: max.100 |

|

|

Size of pay-off bobbin(mm) |

PN800 |

|

Size of take-up bobbin寸(mm) |

PN1000、PN800 |

|

Operation direction |

left to right or right to left |

| Note: In addition to the models in the table, SJ70/25, SJ80/25 and other models can also be provided according to your requirements for different production speeds. | |

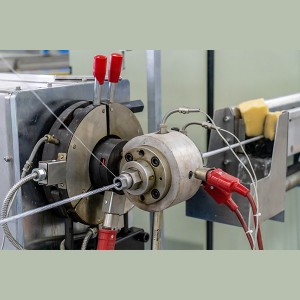

Main Components

The sheath production line is mainly composed of active pay-off, inlet tension storage device, inlet tension equalization device, extruder (including adjustable die head and extruding die), automatic vacuum feeder with hooper dryer, stainless steel cooling water tank, wheel traction device, outlet tension storage device,take-up, and electric control system, etc.

Aluminum foil Mylar tape/Mylar tape longitudinal wrapping device can be selected; inkjet printer needs to be prepared by oneself.

Structure description

The active pay-off is composed of the main frame, the top, and the active pay-off system. The pay-off is controlled by the frequency conversion of the AC motor, and the pay-off spindle is driven by the worm gear reducer.The AC motor drives the lead screw nut through the reducer, pulls the swing arm of the pay-off to swing up or down, and lifts the pay-off bobbin up and down.The pay-off is a shaftless structure, and the pneumatic top clamps the reel. It is also equipped with a mobile trolley for moving the pneumatic clamping bobbin.

Tension control adopts multi-circle guide wheel pendulum type. Gravity is used to control the tension, and the tension can be adjusted by changing the distance between the counterweight and the fulcrum of the pendulum.

The inlet tension equalization device is equipped with a split wheel set and a damping wheel. The damping wheel is connected with the magnetic powder clutch, changing the input voltage of the magnetic powder clutch can change the damping force of the damping wheel.

The extruder frame is welded by steel plate and rectangular steel, and the surface is completely sealed, beautiful and generous, strong and durable.

The extruder is placed horizontally, adopting the most advanced BM high-speed screw in the world, the screw is nitrided, the output is stable, and the outer diameter of the sheath is uniform;

The extruder head adopts a high-precision adjustable eccentric cross head to obtain a high concentricity of the sheath.

The take-up frame is driven by the AC motor through the worm gear reducer to take up the take-up shaft.

The AC motor drives the screw nut through the reducer, pulls the swing arm of the take-up frame to swing up or down, and lifts the take-up reel up and down.

The take-up frame adopts a shaftless structure, and the pneumatic top clamps the bobbin. It is also equipped with a mobile trolley for moving the pneumatic clamping bobbin.

Optional devices

Aluminum foil Mylar tape/Mylar tape longitudinal wrapping device.

The device is suitable for the data cable with the overall shielding of aluminum foil Mylar tape or the overall covering of the cable core with Mylar tape.

The device adopts AC motor frequency conversion speed regulation, and actively releases the tape.

Electronic tension control, which can display and adjust the tension online.

Sequentially arranged, gradually changing die opening size forming die, smooth coating.

Commercial Parts

1. The AC motor adopts Siemens or ABB brand;

2. The AC motor controller adopts Danfoss brand;

3. The DC motor adopts China well-known brand;

4. The DC motor controller adopts Parker brand;

5. The PLC adopts Siemens brand;

6. The main low-voltage electrical appliances adopt Schneider, Siemens and other brands;

7. The display screen adopts Siemens brand;

8. The temperature control meter adopts RKC brand.

FAQ

Q: Can I visit your factory?

A: All the customers from both home and abroad are warmly welcomed to visit our company and factory.

Q: Do you supply the installation and commissioning?

A: Yes, we do as followings:

-As soon as customer informed us the machines are put in the right place, we will send both mechanical and electrical engineer for machine start up.

-No-load testing: After machine installed completely, we make no-load testing first.

-With-load testing: Usually we will can produce 3 different wires to make load testing.

-Acceptance report: After the buyer confirms that machine can reach all specification under contract, the acceptance report will be signed for our record that machine will be in guarantee period.

Q: What information should I offer to get a detailed quotation from you?

A: For single machine: Usually we need to know inlet wire size, outlet wire size to be produced, productivity, pay off and take up size to choose the right machine.

For new cable plant or new cable production line, we need to know the datasheet of cables to be produced, the productivity, the standards to be followed, etc to design all machines needed.

Q: Can you supply the auxiliary equipment along with the machines?

A: Yes, definitely.

We has supplied heat exchanger, copper/aluminum powder filter machine, cooling tower, chiller, air compressor, drawing dies, pointing machine, cold welders, bobbins etc. with our machines.

Q: Could you do the design for the whole plant?

A: Yes, this is our advantage.

With the data sheet of cable to be produced, the standard your cables should follows, the productivity you expected. Our engineer on production technology and machinery will make design of production machines, test equipment, accessories like bobbins, dies, rewinding lines and materials needed.

Q: How can I know the status of my order?

A: We have our OA system on tracking the production.

For any of your request we can send photos and videos of your order, also we can use FACETIME to let you know the production.

Q: How do you work on the inspection before delivery?

A: We will make dynamic balance testing, levelness testing, noise testing, etc. during production.

After production finished, usually we make no-load running of each machine before delivery. Customers are welcomed to attend the inspection.

Q: What exhibitions will you attend, can we meet in the fair?

A: Dusseldorf International Wire and Cable Fair;

Wire South America Fair;

International Wire and Cable Fair in Shanghai;

International Istanbul Wire Fair, etc.

wire Southeast Asia Fair, etc.