-

Process Control Requirements for Cat.6 and Cat.7 LAN Cables

For the structural characteristics and performance requirements of Cat. 6 and Cat.7 LAN cables, companies should work hard on production process to meet the requirements of standards for LAN cable performance indicators. (1) Insulation process The elongation rate of copper wire should be stably c...Read more -

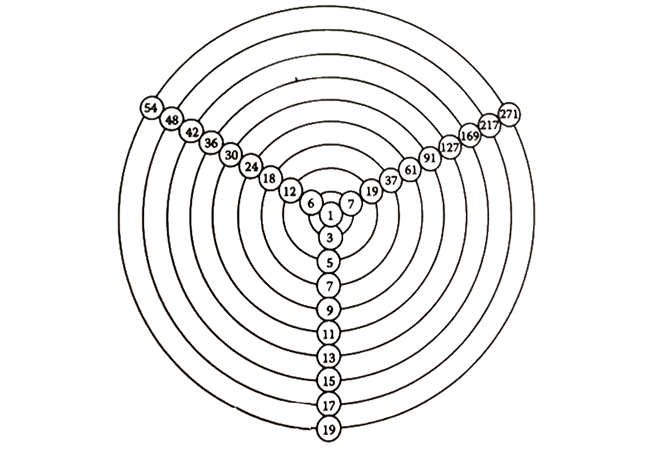

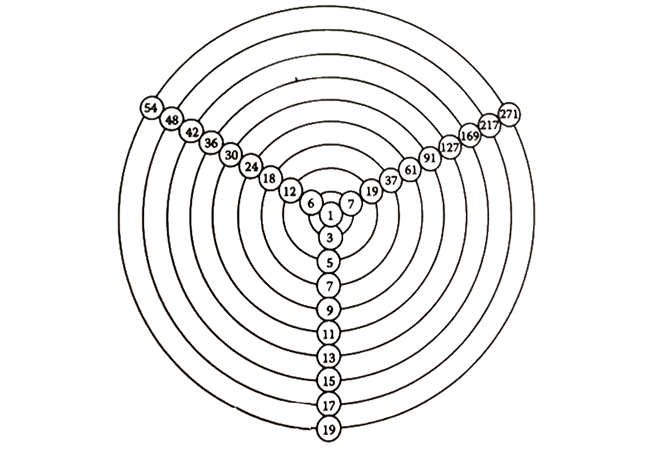

Cable Conductor Stranding Methods and Stranding Equipment Recommendations

Conductor stranding refers to stranding several single wires with the same or different diameters together in a certain direction and according to certain rules to form an overall stranded wire core. Large cross-section solid conductors cannot be laid, formed and connected smoothly because they a...Read more -

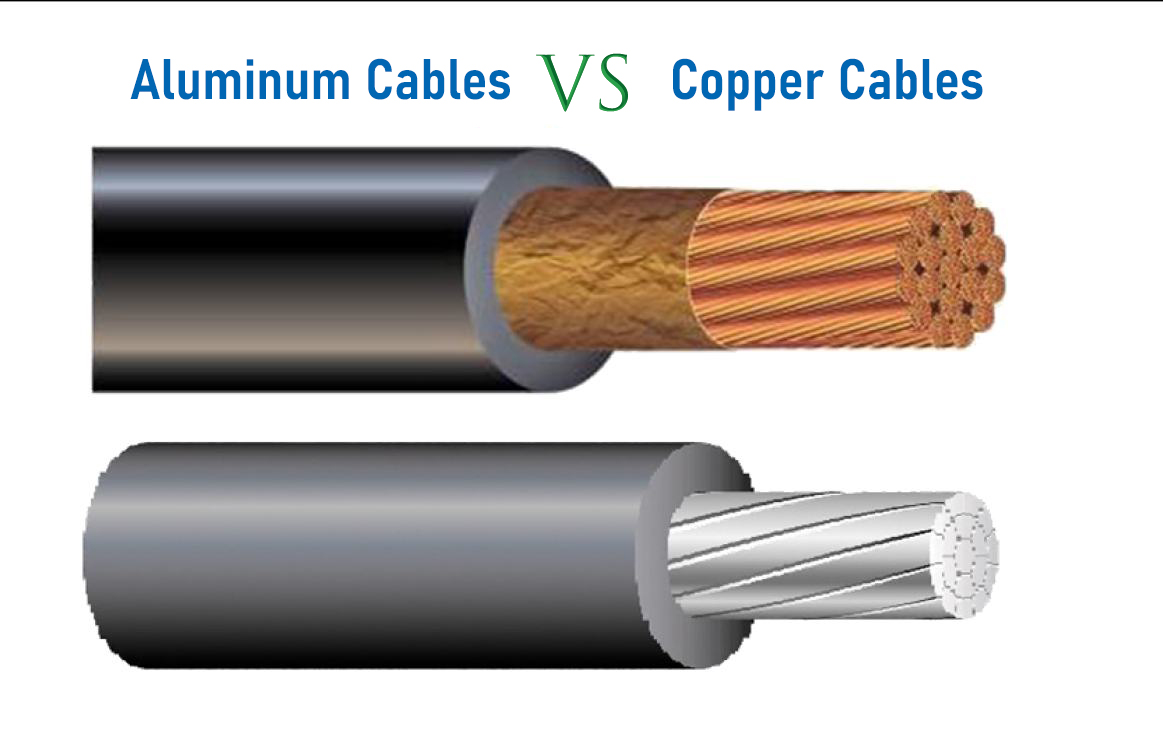

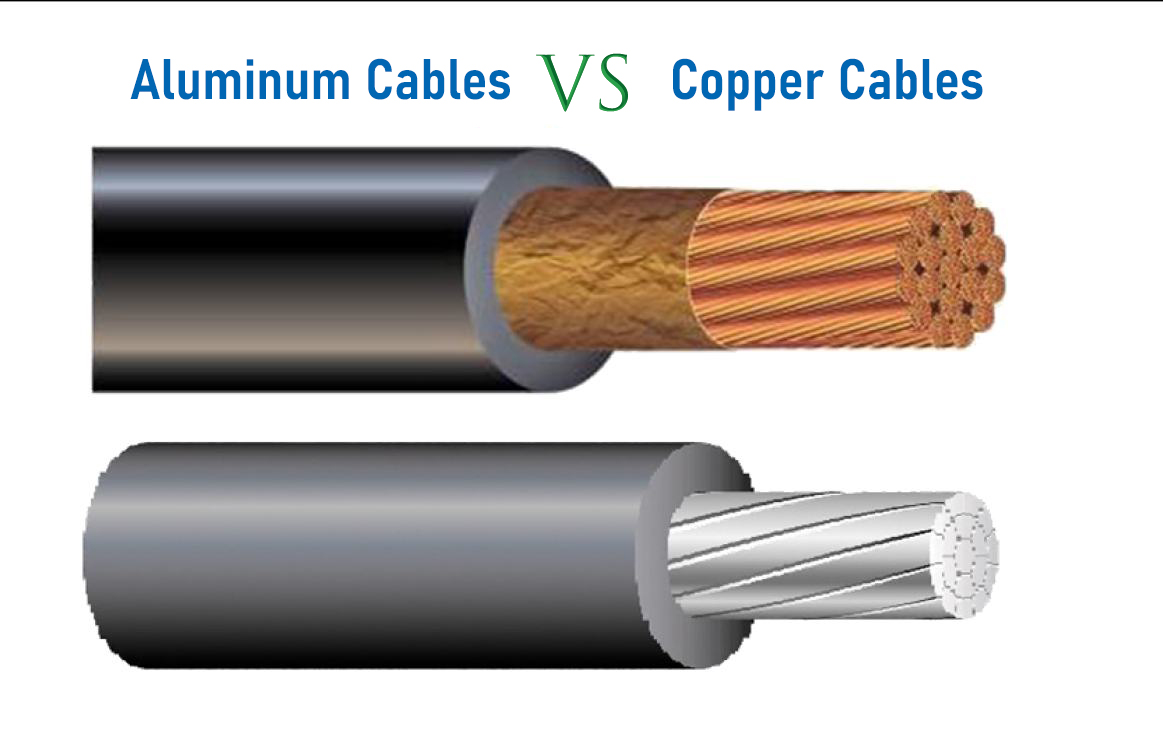

Will Aluminum Alloy Cables Replace the Copper Cables Market?

Are aluminum alloy cables the best substitute for copper cables? To understand this problem, we need to understand the difference in performance, price, and usage ratio of aluminum alloy cables and copper cables. Now LINT TOP will discuss with you whether aluminum alloy cables are the best choice...Read more -

Offshore Wind Power Enters the “Fast Lane” of Development

China's offshore wind power industry is developing at an alarming rate. According to industry analysts, as various parts of China accelerate the construction of offshore wind power projects, other offshore wind power projects originally scheduled to start construction before the end of this year ...Read more