Best quality Cold Pressure Welder - Double Head Vertical Taping Machine – LINT TOP

Product Details

Best quality Cold Pressure Welder - Double Head Vertical Taping Machine – LINT TOP Detail:

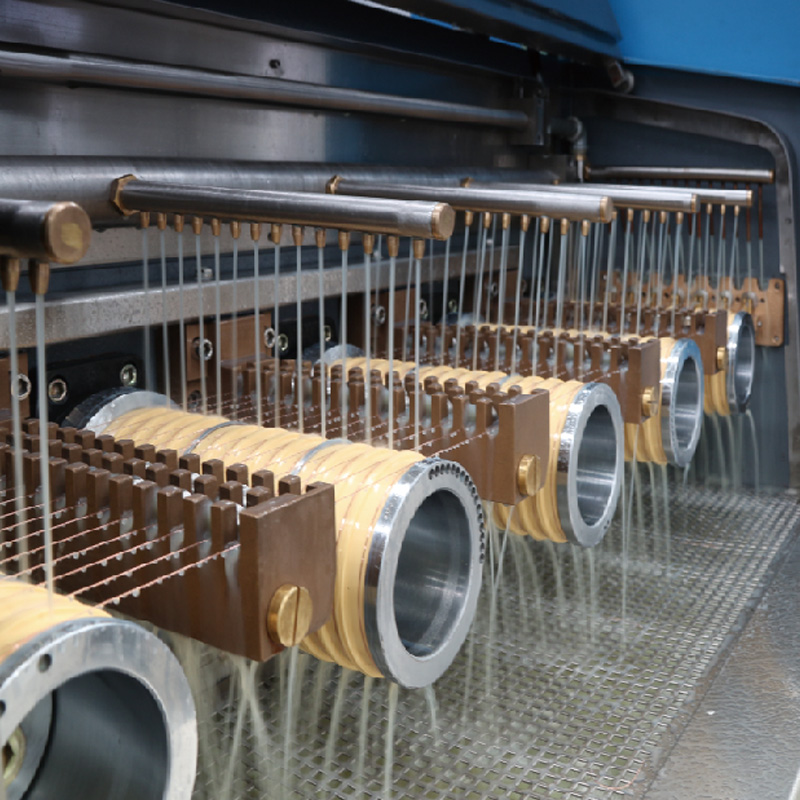

With the continuous development of science and technology, the cables used in the power supply devices of some special equipment are getting higher and higher. The cables are required to have properties of fire-resistance, wear-resistance, acid and alkali resistance and others. Among them, in order to meet the fire-resistance of the cable, the fire-resistant mica tape is usually wrapped around the cable because the fire-resistant mica tape is a fire-resistant insulating material commonly used in cables. In the production process of the cable, the tape of insulating material is usually wrapped around the cable conductors according to certain rules. In order to ensure the uniformity and tightness of the wrapping, the taping machine is usually used to wrap the mica tape, polyester tape and non-woven fabric on the cable .

1. Introduction

The vertical double heads taping machine provided by our company is a specialized equipment for wrapping flame-retardant, fire-resistance and special cables. It has the characteristics of high taping speed, stable pitch, controllable tension and strong stability.

2. Technical Parameters

|

Pay-off (mm) |

Φ400-Φ630 (Independent, shaftless), tension controller by friction pad |

|

Inner wire diameter (mm) |

Φ1-Φ7 (Hard wire no more than 2.76mm) |

|

Number of taping head |

2 heads |

|

Taping motor |

Frequency conversion motor (Each head controlled only) |

|

Tension control of the taping head |

Servo motor (DELTA) control tension |

|

Pitch (mm) |

3-18 |

|

Max. taping speed (rpm) |

2500 |

|

Tape size (mm) |

Outer dia.: 300; Inner dia.: 76 |

|

Diameter of the caterpillar wheel(mm) |

400mm |

|

Tape storage device (mm) |

200mm |

|

Taping material |

Mica tape, polyester tape, non-woven fabric |

|

Take-up (mm) |

Φ800 (Attached on the machine,shaftless), controlled by torque motor |

3. Features

(1) The tape disc is available pad tape disc type and bobbin tape disc type, and the size can be customized according to tape size requirements;

(2) When the tape breaks, the equipment can automatically stop;

(3) Optional mechanical friction or magnetic powder tension for pay-off tension control;

(4) Take-up tension control can choose torque motor or magnetic powder tension.

Product detail pictures:

Related Product Guide:

To be the stage of realizing dreams of our employees! To build a happier, far more united and far more specialist team! To reach a mutual profit of our customers, suppliers, the society and ourselves for Best quality Cold Pressure Welder - Double Head Vertical Taping Machine – LINT TOP , The product will supply to all over the world, such as: Guinea, Salt Lake City, Italy, Good quality and reasonable price have brought us stable customers and high reputation. Providing 'Quality Products, Excellent Service, Competitive Prices and Prompt Delivery', we are now looking forward to even greater cooperation with overseas customers based on mutual benefits. We'll work whole-heartedly to improve our solutions and services. We also promise to work jointly with business partners to elevate our cooperation to a higher level and share success together. Warmly welcome you to visit our factory sincerely.

FAQ

Q: Can I visit your factory?

A: All the customers from both home and abroad are warmly welcomed to visit our company and factory.

Q: Do you supply the installation and commissioning?

A: Yes, we do as followings:

-As soon as customer informed us the machines are put in the right place, we will send both mechanical and electrical engineer for machine start up.

-No-load testing: After machine installed completely, we make no-load testing first.

-With-load testing: Usually we will can produce 3 different wires to make load testing.

-Acceptance report: After the buyer confirms that machine can reach all specification under contract, the acceptance report will be signed for our record that machine will be in guarantee period.

Q: What information should I offer to get a detailed quotation from you?

A: For single machine: Usually we need to know inlet wire size, outlet wire size to be produced, productivity, pay off and take up size to choose the right machine.

For new cable plant or new cable production line, we need to know the datasheet of cables to be produced, the productivity, the standards to be followed, etc to design all machines needed.

Q: Can you supply the auxiliary equipment along with the machines?

A: Yes, definitely.

We has supplied heat exchanger, copper/aluminum powder filter machine, cooling tower, chiller, air compressor, drawing dies, pointing machine, cold welders, bobbins etc. with our machines.

Q: Could you do the design for the whole plant?

A: Yes, this is our advantage.

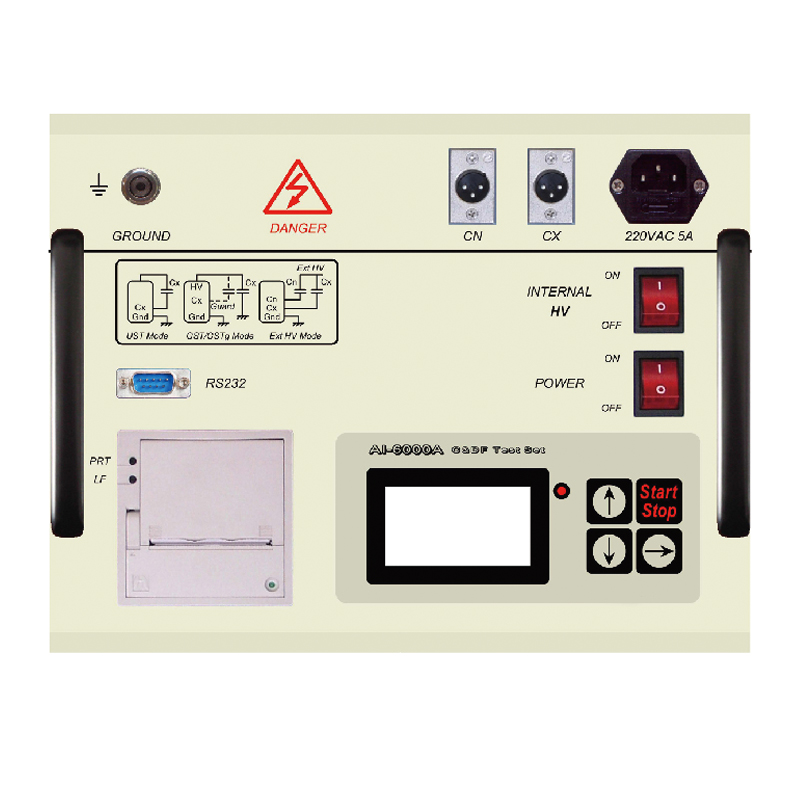

With the data sheet of cable to be produced, the standard your cables should follows, the productivity you expected. Our engineer on production technology and machinery will make design of production machines, test equipment, accessories like bobbins, dies, rewinding lines and materials needed.

Q: How can I know the status of my order?

A: We have our OA system on tracking the production.

For any of your request we can send photos and videos of your order, also we can use FACETIME to let you know the production.

Q: How do you work on the inspection before delivery?

A: We will make dynamic balance testing, levelness testing, noise testing, etc. during production.

After production finished, usually we make no-load running of each machine before delivery. Customers are welcomed to attend the inspection.

Q: What exhibitions will you attend, can we meet in the fair?

A: Dusseldorf International Wire and Cable Fair;

Wire South America Fair;

International Wire and Cable Fair in Shanghai;

International Istanbul Wire Fair, etc.

wire Southeast Asia Fair, etc.