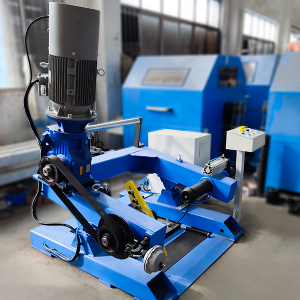

Cold Welder

Product Details

1. Introduction

Electrical cable is used as the intermediate link to connect each functional parts of the whole electronic system. Any loose contact or low quality welding joint will threaten the operation security of entire system. Cold welder is mainly used in wire drawing process.

2. Applied Material

Generally, the cold welder is suitable for metal wires with low hardness and good ductility like aluminum wires and copper (alloy) wires.

3. Welding Classification

The welding process is simple and easy to operate, mainly including cold welding and hot welding. Cold welding is a method to achieve solid-state welding through applying pressure to make metal strong plastic deformation at room temperature. The applied pressure generally should be higher than the material yield strength to deform by 60%~90%.

And the hot welding is carried out higher than the room temperature between 100~300℃.

Under the cold welding, the oxide or other pollutant on the surface of aluminum and copper are broken and removed under the pressure.

The bonding surface of aluminum and copper neither produce welding defect assosiated with melting and solidification, nor melt occur.

When using hot welding, the joints are generally not required to be cleaned before welding, and the welding heating temperature is lower than the eutectic point of aluminum and copper, and the aluminum and copper base materials are not melted. In the formation of aluminum and copper mechanical mixing zone, increase the pressure to improve the microstructure, can refine the compound, and improve the strength of the joint.

4. Matched Dies and Maintenance

4.1 The dies for cold welder are made by high quality steel and treated by vaccum quenching. Its hardness is about HRC 56 ~ 60 with the characteristics of small deformation and wear resistance. When using, in addition to selecting a die that matches the wire specifications, in order to extend the service life of the die and achieve a better welding result, the maintenance is also very important.

4.2 It is necessary to take it apart and wipe it with a clean white cloth every day after using (We suggest using compressed air to blow away the dirt inside the dies ) to ensure no foreign bodies in the four small blocks and the column pin cannot be rusted. Especially in relatively humid coastal areas, the dies should be sprayed with lubricants when not used for a long time, and should not be wrapped with a damp cloth to prevent rust.

In the case of daily use, you only need to wipe it cleanbut bot with any lubricant. The wire groove in dies is very important, wipe it clean every day to prevent the wire groove from rusting. If there is oil or dirt on the wire head during wiring, clean it before wiring.

If it has not been connected more than 20 times, take out the die and clean inside of it, then continue.

5. Technical Parameters and Advantages

We provide hand-held welder(LT-10A), table type welder(LT-3B,LT-4A) and hydraulic type welder(LT-1510B, LT-2013B)

Welding range and application material are as the following table:

|

Model |

LT-3B |

LT-4A |

LT-10A |

LT-1510B |

LT-2013B |

|

Range of Wire (mm) |

Cu: Φ0.80-Φ4.00 |

Cu: Φ0.80-Φ4.20

|

Cu: Φ0.05-Φ0.50 |

Cu: Φ3-Φ10 |

Cu: Φ5-Φ12.5

|

|

Al: Φ0.80-Φ5.50 |

Al: Φ0.80-Φ5.30 Al Alloy: Φ1.00-Φ4.00 |

Al: Φ0.07-Φ0.50 |

Al: Φ3-Φ15 |

Al: Φ5-Φ18 Al Alloy: Φ5-Φ9.50 |

The quality of cold welding is better than the traditional method with the following advantages:

(1) No need to treat the welding part ends before welding.

(2)No need to heat during welding process, no silver welding pads needed, which can save energy, reduce production costs, and with a relatively clean working environment.

(3) Cold welding directly put the wires into the die, the operation is relatively convenient and simple, easy to master.

(4) Compared with resistance welding, the cold welding head has smaller flash which is easy to remove and smooth.

(5) There is no welding heat affected zone on the cold welding head, and no softening zone and brittle metal mesophase. Therefore, the joint has excellent properties such as conductivity and corrosion resistance.

(6) The joint is strengthened due to deformation and hardening during cold welding. The strength of the welded joint shall not be lower than base material.

FAQ

Q: Can I visit your factory?

A: All the customers from both home and abroad are warmly welcomed to visit our company and factory.

Q: Do you supply the installation and commissioning?

A: Yes, we do as followings:

-As soon as customer informed us the machines are put in the right place, we will send both mechanical and electrical engineer for machine start up.

-No-load testing: After machine installed completely, we make no-load testing first.

-With-load testing: Usually we will can produce 3 different wires to make load testing.

-Acceptance report: After the buyer confirms that machine can reach all specification under contract, the acceptance report will be signed for our record that machine will be in guarantee period.

Q: What information should I offer to get a detailed quotation from you?

A: For single machine: Usually we need to know inlet wire size, outlet wire size to be produced, productivity, pay off and take up size to choose the right machine.

For new cable plant or new cable production line, we need to know the datasheet of cables to be produced, the productivity, the standards to be followed, etc to design all machines needed.

Q: Can you supply the auxiliary equipment along with the machines?

A: Yes, definitely.

We has supplied heat exchanger, copper/aluminum powder filter machine, cooling tower, chiller, air compressor, drawing dies, pointing machine, cold welders, bobbins etc. with our machines.

Q: Could you do the design for the whole plant?

A: Yes, this is our advantage.

With the data sheet of cable to be produced, the standard your cables should follows, the productivity you expected. Our engineer on production technology and machinery will make design of production machines, test equipment, accessories like bobbins, dies, rewinding lines and materials needed.

Q: How can I know the status of my order?

A: We have our OA system on tracking the production.

For any of your request we can send photos and videos of your order, also we can use FACETIME to let you know the production.

Q: How do you work on the inspection before delivery?

A: We will make dynamic balance testing, levelness testing, noise testing, etc. during production.

After production finished, usually we make no-load running of each machine before delivery. Customers are welcomed to attend the inspection.

Q: What exhibitions will you attend, can we meet in the fair?

A: Dusseldorf International Wire and Cable Fair;

Wire South America Fair;

International Wire and Cable Fair in Shanghai;

International Istanbul Wire Fair, etc.

wire Southeast Asia Fair, etc.