Automatic Double Take-up

Product Details

1. Introduction

The double-reel traversing and take-up device is mainly composed of take-up unit, bobbin lifting and clamping unit, traversing unit, switching and moving mechanism, catching and cutting mechanism and the body frame.

With a vertical column type arrangement, the box body which has good stability is welded by steel plates. Adopting high-quality pneumatic components, working pressure and traversing pitch can be adjusted. With compact structure and small occupation space, it is basically can achieve non-stop production and high production efficiency.

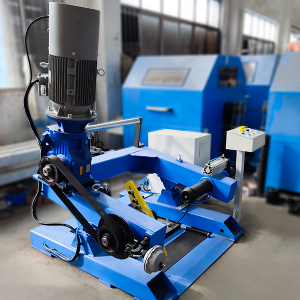

The take-up unit is composed of 18.5KW AC variable frequency motor, synchronous belt and synchronous pulley. The motor transmits power through the synchronous belt, and drives the large pulley which connected with the take-up shaft to rotate, thus driving the take-up bobbin to rotate to complete the take-up.

The bobbin lifting and clamping unit is composed of lifting frame and clamping pintle. After the spool is pushed into the lifting frame, the lifting cylinder control button is started manually, and it stops automatically when it is lifted to the specified height pneumatically, and then the clamping center is automatically extended under the control of the cylinder, so that the bobbin and the take-up shaft are tightly fixed together.

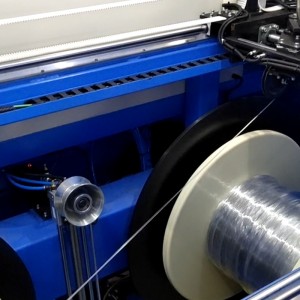

The wire traversing unit is composed of 1kW servo motor, a set of synchronous belts, a ball screw and a moving mechanism. The motor drives the ball screw to rotate through a set of synchronous belt wheels, thereby driving the wire and cable guide wheel to reciprocate linearly on the reel, so that the wires are evenly arranged on the surface of the reel, which can meet the requirements of different cable pitches. The moving mechanism is installed on the beam above the back of the take-up reel and consists of 750W AC motor, reducer, timing belt wheel, timing belt and moving bracket. The motor is driven by the reducer to rotate the synchronous belt wheel when moving, and the moving bracket is driven by the synchronous belt to move on the crossbeam. When it reaches the required position, it automatically stops. The structure is simple and the operation is reliable.

The wire catching cutting mechanism is installed on the middle column behind the two reels, and it is composed of a swing cylinder, a catch hook, a push rod and a push rod cylinder. When changing the reel, the wire is first pushed to the appropriate position by the push rod, and then the catch hook catch the wire, and then use the clamp on the take-up reel to clamp the wire to realize the fast switching between the two reels through the cutter, which is stable and reliable.

The overall frame is welded by profiles, with a firm and beautiful appearance. The windows are equipped with plexiglass, which is convenient for observing the production operation.

Line entry mode: Top entry

The electric control system adopts PLC logic control and touch screen operation.

2. Technical Parameters

***The below technical parameters is specially designed for 800mm, we can also provide other size take-up. If you have requirements, please feel free to contact us.***

Bobbin size: Φ500mm, Φ630mm, Φ800mm.

Applicable wire diameter: Max.Φ6mm

Take-up speed: Max. 400m/min (When bobbin size is Φ800mm)

Take-up motor: 18.5KW AC variable frequency motor (2 units)

Traversing unit: 1Kw servo motor + ball screw wire traversing

Walking motor: 750w AC motor with brake function

Bobbin-changing type: Dual-bobbin can be automatically switched at high speed and the success rate of bobbin-changing is greater than 98%.

Loading and unloading bobbins type: Loading and unloading reels manually, lifting pneumatically, clamping pneumatically, equipped with loading and unloading r reel guide roller brackets.

Bobbin-changing: Automatic switch between empty and full bobbins, the length of bobbin-changing can be preset, and automatic disk change from rice to rice (With independent meter counter and encoder meter.)

Bobbin-changing length error: Less than 10m

Catching success rate for switching bobbin: 98%

Encoder control, traversing pitch can be set on the touch screen.

PLC, inverter: Siemens S7-200 Smart, smart touch screen.

Bearing: NSK brand

Pneumatic components: AirTAC brand

Control instructions: This machine is operated by an independent electric box, with reserved emergency stop, linkage interface, and meter output interface.

FAQ

Q: Can I visit your factory?

A: All the customers from both home and abroad are warmly welcomed to visit our company and factory.

Q: Do you supply the installation and commissioning?

A: Yes, we do as followings:

-As soon as customer informed us the machines are put in the right place, we will send both mechanical and electrical engineer for machine start up.

-No-load testing: After machine installed completely, we make no-load testing first.

-With-load testing: Usually we will can produce 3 different wires to make load testing.

-Acceptance report: After the buyer confirms that machine can reach all specification under contract, the acceptance report will be signed for our record that machine will be in guarantee period.

Q: What information should I offer to get a detailed quotation from you?

A: For single machine: Usually we need to know inlet wire size, outlet wire size to be produced, productivity, pay off and take up size to choose the right machine.

For new cable plant or new cable production line, we need to know the datasheet of cables to be produced, the productivity, the standards to be followed, etc to design all machines needed.

Q: Can you supply the auxiliary equipment along with the machines?

A: Yes, definitely.

We has supplied heat exchanger, copper/aluminum powder filter machine, cooling tower, chiller, air compressor, drawing dies, pointing machine, cold welders, bobbins etc. with our machines.

Q: Could you do the design for the whole plant?

A: Yes, this is our advantage.

With the data sheet of cable to be produced, the standard your cables should follows, the productivity you expected. Our engineer on production technology and machinery will make design of production machines, test equipment, accessories like bobbins, dies, rewinding lines and materials needed.

Q: How can I know the status of my order?

A: We have our OA system on tracking the production.

For any of your request we can send photos and videos of your order, also we can use FACETIME to let you know the production.

Q: How do you work on the inspection before delivery?

A: We will make dynamic balance testing, levelness testing, noise testing, etc. during production.

After production finished, usually we make no-load running of each machine before delivery. Customers are welcomed to attend the inspection.

Q: What exhibitions will you attend, can we meet in the fair?

A: Dusseldorf International Wire and Cable Fair;

Wire South America Fair;

International Wire and Cable Fair in Shanghai;

International Istanbul Wire Fair, etc.

wire Southeast Asia Fair, etc.