Rewinding Line

Product Details

1. Introduction

Rewinding line is used to rewind bare conductors, insulated wire, cable or sheath wire from one type/size of reel to another suitable type/size of reel in order to meet the production requirements of the next process or to meet the delivery of products of the required length and packaging requirements of the customer.

Our rewinding lines are designed to meet the requirements of our customers for rewinding a wide range of products, providing them with the best possible solution.

The rewinding line consists of a pay-off device, an alignment device, a tension dancer, a traction machine, a metre counter, a wire frame, a take-up device and an electrical control system. We can also match online inspection instruments such as diameter measuring instrument and sparking machine according to customer's requirements in order to achieve online inspection of cable outer diameter and cable surface defects.

2. Features

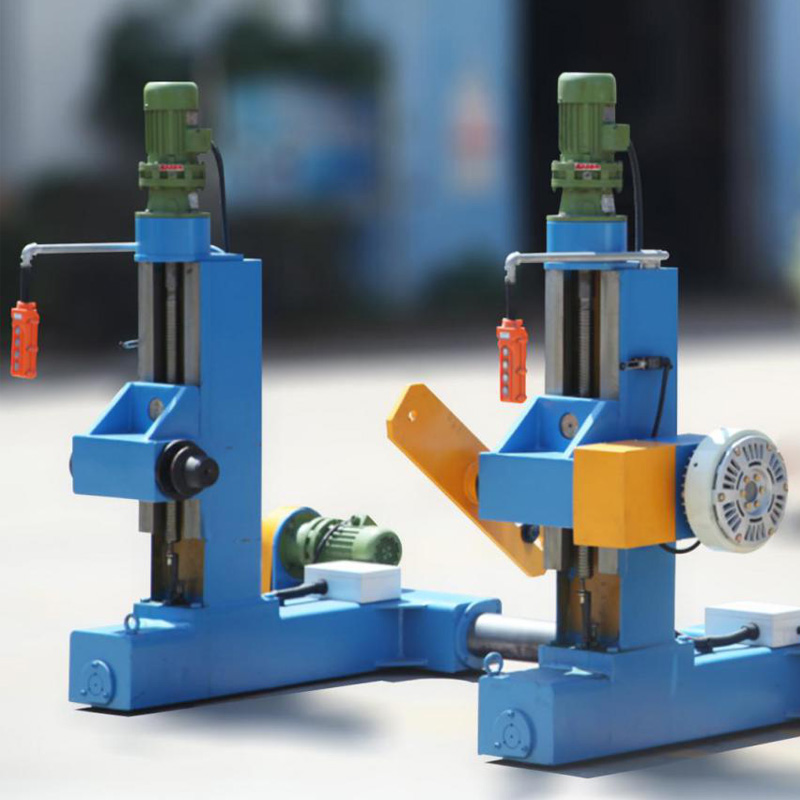

1) Different forms of take-up and pay-off devices can be configured according to customer requirements, such as: cantilever type, column type, gantry walking type, etc.

2) The forms of pay-off are active, passive and active-passive to meet the pay-off of different wire diameter products.

3) can be equipped with different forms of braking devices, such as: magnetic powder braking, mechanical braking, etc., in order to prevent disorderly stopping of the wire when rewinding at high speed.

4) With functions such as wire breakage stop, spark detection short circuit alarm, outside diameter overrun alarm, reverse wire length setting, meter to stop, etc.

5) The main electrical appliances adopt international famous brands, such as: Siemens, Schneider, NSK, SKF, etc.

3. Models

We offer rewinding lines that can be loaded with metal, plastic and wooden bobbins that meet DIN standards.

The main types are as follows, but are not limited to the following types of rewinding lines.

LT630 - for rewinding on bobbins with a maximum diameter of 630 mm

LT800 - for rewinding on bobbins with a maximum diameter of 800 mm

LT1000 - for rewinding on bobbins with a maximum diameter of 1000 mm

LT1250 - for rewinding on bobbins with a maximum diameter of 1250 mm

LT1600 - for rewinding on bobbins with a maximum diameter of 1600 mm

LT2000 - for rewinding on bobbins with a maximum diameter of 2000 mm

LT2500 - for rewinding on bobbins with a maximum diameter of 2500 mm

FAQ

Q: Can I visit your factory?

A: All the customers from both home and abroad are warmly welcomed to visit our company and factory.

Q: Do you supply the installation and commissioning?

A: Yes, we do as followings:

-As soon as customer informed us the machines are put in the right place, we will send both mechanical and electrical engineer for machine start up.

-No-load testing: After machine installed completely, we make no-load testing first.

-With-load testing: Usually we will can produce 3 different wires to make load testing.

-Acceptance report: After the buyer confirms that machine can reach all specification under contract, the acceptance report will be signed for our record that machine will be in guarantee period.

Q: What information should I offer to get a detailed quotation from you?

A: For single machine: Usually we need to know inlet wire size, outlet wire size to be produced, productivity, pay off and take up size to choose the right machine.

For new cable plant or new cable production line, we need to know the datasheet of cables to be produced, the productivity, the standards to be followed, etc to design all machines needed.

Q: Can you supply the auxiliary equipment along with the machines?

A: Yes, definitely.

We has supplied heat exchanger, copper/aluminum powder filter machine, cooling tower, chiller, air compressor, drawing dies, pointing machine, cold welders, bobbins etc. with our machines.

Q: Could you do the design for the whole plant?

A: Yes, this is our advantage.

With the data sheet of cable to be produced, the standard your cables should follows, the productivity you expected. Our engineer on production technology and machinery will make design of production machines, test equipment, accessories like bobbins, dies, rewinding lines and materials needed.

Q: How can I know the status of my order?

A: We have our OA system on tracking the production.

For any of your request we can send photos and videos of your order, also we can use FACETIME to let you know the production.

Q: How do you work on the inspection before delivery?

A: We will make dynamic balance testing, levelness testing, noise testing, etc. during production.

After production finished, usually we make no-load running of each machine before delivery. Customers are welcomed to attend the inspection.

Q: What exhibitions will you attend, can we meet in the fair?

A: Dusseldorf International Wire and Cable Fair;

Wire South America Fair;

International Wire and Cable Fair in Shanghai;

International Istanbul Wire Fair, etc.

wire Southeast Asia Fair, etc.