High Speed Insulation Extrusion Linein - China Manufacturers, Suppliers, Factory

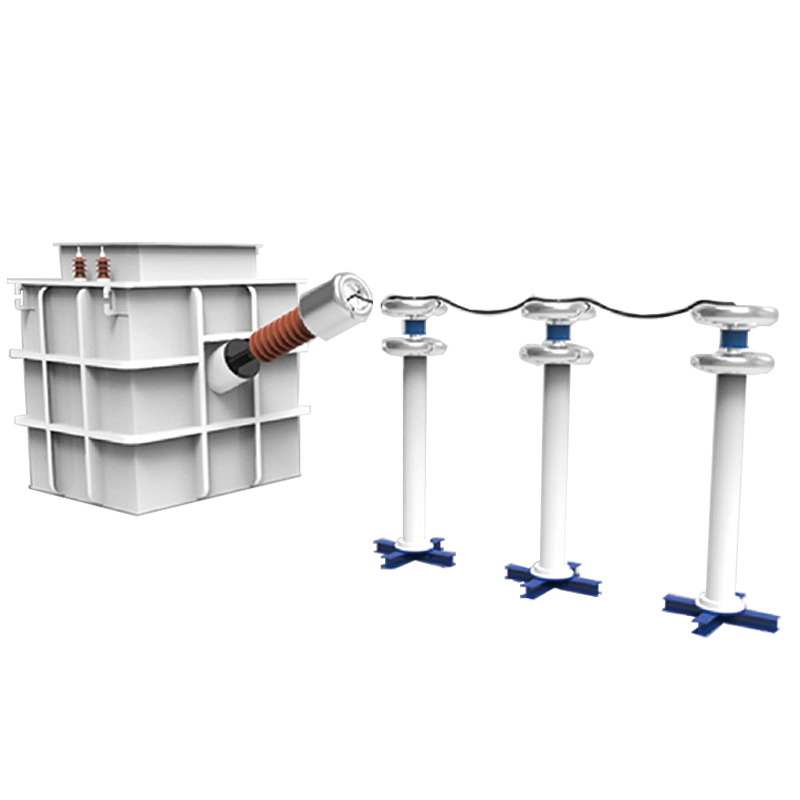

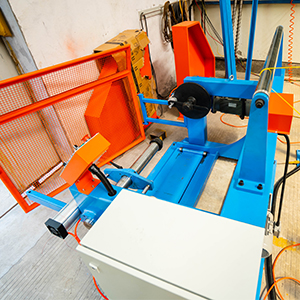

Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs for High Speed Insulation Extrusion Linein, Cable Laying Machine, Cable Printer, Braiding Machines,Uv Laser Marking Machine. "Making the Products of Large Quality" is definitely the everlasting purpose of our enterprise. We make unremitting endeavours to know the target of "We Will Always Hold in Pace along with the Time". The product will supply to all over the world, such as Europe, America, Australia,Guatemala, Thailand,Colombia, French.We have the best products and professional sales and technical team.With the development of our company, we are able to provide customers best products, good technical support, perfect after-sales service.

Related Products