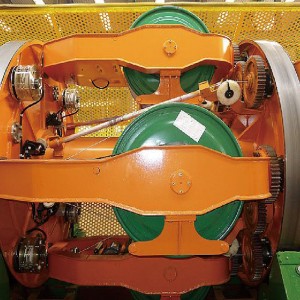

Double Twist Stranding Machine

Product Details

The conductors of the power cables mainly adopt the stranded structure by using stranding machines such as tubular strander and rigid frame strander for layered and directional stranding. For power cables with a number of conductors of 19 or less, a layered and co-directional twisting method can be used, which is a more commonly used twisting method at present. This requires a high-efficiency, low-cost stranding machine to meet the needs of the market, hence a new type of high-speed stranding machine came into being.

We can provide LT1250 and LT1600 high-speed stranding machines, which are mainly used for stranding 7-19 copper wires, aluminum wires/aluminum alloy wires, and also for stranding 2 to 4 PVC insulated core wires. The high-speed stranding machine we provide is a double-pitch stranding machine (double twisting machine), which can form two stranding pitches per rotating of the bow, and the production efficiency is twice that of the ordinary single-pitch stranding machine.

The LT1250 and LT1600 high-speed stranding machines can partly replace tubular strander and rigid frame strander. Compared with tubular strander and rigid frame strander that can produce such products, this machine has the characteristics of high production efficiency and less floor space. It is currently the most cost-effective equipment for stranding 19 or less power cable conductors.

Compared with the traditional stranding machine,the LT1250 and LT1600 double twist stranding machines not only have higher production efficiency, but also can compress the stranded conductor.

1. Features

The high-speed stranding machine we provide has the following characteristics:

(1) Using carbon fiber synthetic twisting bow, which is strong and can ensure high-speed rotation;

(2) Each part of the whole machine (twisting bow, traction, take-up) is driven by independent motors;

(3) The sound insulation adopts a closed safety cover with low noise under 85db;

(4) Stepless pitch adjustment which can be set on the touch screen;

(5) Man-machine interface control system, easy to operate;

(6) With compression device for stranding wires;

(7) The take-up tension is controlled by an independent motor;

(8) Adopt precision type take-up tension control system;

(9) The electromagnetic brake is used for braking which can automatically brake and stop when the internal and external wires are broken or various failures.

2. Main Technical Parameters

|

Model |

LT1250 |

LT1600 |

|

|

Stranded cross sectional area(mm2) |

Copper wires |

10~50 |

10~90 |

|

Aluminum wires/Aluminum alloy wires |

10~70 |

10~120 |

|

|

The outer diameter of the stranded insulated wire(mm) |

5~15 |

5~20 |

|

|

Stranding speed(rpm) |

Max.800 |

Max.500 |

|

|

Stranding pitch(mm) |

40~350 |

40~350 |

|

|

Stranding direction |

S or Z |

S or Z |

|

|

Take-up bobbin(mm) |

800~1250 |

1200~1600 |

|

Taking 7 regular stranded conductors as an example, the following table shows the capacity comparison of LT1250 high-speed stranding machine, high-speed 630-type tubular stranding machine and ordinary 630-type tubular stranding machine:

Capacity table of LT1250 double twist stranding machine

|

Nominal cross sectional area(mm2) |

Wire diameter of conductor(mm) |

Stranded wire outer diameter (mm) |

lay ratio |

Stranding pitch(mm) |

Actual cross-sectional area(mm2) |

Weight per meter(kg/m) |

Stranding speed(rpm) |

Production speed(m/min) |

Capacity (kg/h) |

|

10 |

1.38 |

4.14 |

15 |

62.1 |

10.47 |

0.09 |

700 |

86.9 |

486.1 |

|

16 |

1.78 |

5.34 |

15 |

80.1 |

17.42 |

0.16 |

650 |

104.1 |

968.6 |

|

25 |

2.15 |

6.45 |

15 |

96.75 |

25.41 |

0.23 |

600 |

116.1 |

1575.5 |

|

35 |

2.52 |

7.56 |

15 |

113.4 |

34.91 |

0.31 |

600 |

136.1 |

2536.9 |

|

50 |

3.0 |

9.0 |

15 |

135 |

49.48 |

0.44 |

500 |

135.0 |

3566.9 |

Capacity table of high-speed LT 630 tubular stranding machine

|

Nominal cross sectional area(mm2) |

Wire diameter of conductor(mm) |

Stranded wire outer diameter (mm) |

lay ratio |

Stranding pitch(mm) |

Actual cross-sectional area(mm2) |

Weight per meter(kg/m) |

Stranding speed(rpm) |

Production speed(m/min) |

Capacity(kg/h) |

|

10 |

1.38 |

4.14 |

15 |

62.1 |

10.47 |

0.09 |

500 |

31.1 |

174.6 |

|

16 |

1.78 |

5.34 |

15 |

80.1 |

17.42 |

0.16 |

500 |

40.1 |

372.5 |

|

25 |

2.15 |

6.45 |

15 |

96.75 |

25.41 |

0.23 |

500 |

48.4 |

656.5 |

|

35 |

2.52 |

7.56 |

15 |

113.4 |

34.91 |

0.31 |

500 |

56.7 |

1057.1 |

|

50 |

3.0 |

9.0 |

15 |

135 |

49.48 |

0.44 |

500 |

67.5 |

1783.5 |

Capacity table of normal LT 630 tubular stranding machine

|

Nominal cross sectional area(mm2) |

Wire diameter of conductor(mm) |

Stranded wire outer diameter (mm) |

lay ratio |

Stranding pitch(mm) |

Actual cross-sectional area(mm2) |

Weight per meter(kg/m) |

Stranding speed(rpm) |

Production speed(m/min) |

Capacity(kg/h) |

|

10 |

1.38 |

4.14 |

15 |

62.1 |

10.47 |

0.09 |

300 |

18.6 |

104.2 |

|

16 |

1.78 |

5.34 |

15 |

80.1 |

17.42 |

0.16 |

300 |

24.0 |

223.5 |

|

25 |

2.15 |

6.45 |

15 |

96.75 |

25.41 |

0.23 |

300 |

29.0 |

393.9 |

|

35 |

2.52 |

7.56 |

15 |

113.4 |

34.91 |

0.31 |

300 |

34.0 |

634.2 |

|

50 |

3.0 |

9.0 |

15 |

135 |

49.48 |

0.44 |

300 |

40.5 |

1070.1 |

Comparison table of production capacity of LT1250 double twist stranding machine and 630 tubular stranding machine

|

Nominal cross-sectional area (mm2) |

Capacity(kg/h) |

Capacity comparison |

|||

|

LT1250 |

High-speed LT 630 tubular stranding machine |

Normal LT 630 tubular stranding machine |

LT1250 and High speed 630 tubular stranding machine |

LT1250 and Normal 630 tubular stranding machine |

|

|

10 |

486.1 |

174.6 |

104.2 |

2.78 |

4.67 |

|

16 |

968.6 |

372.5 |

223.5 |

2.6 |

4.33 |

|

25 |

1575.5 |

656.5 |

393.9 |

2.4 |

4.0 |

|

35 |

2536.9 |

1057.1 |

634.2 |

2.4 |

4.0 |

|

50 |

3566.9 |

1783.5 |

1070.1 |

2.0 |

3.33 |

From the above capacity comparison table, it can be concluded that the capacity of the LT1250 high-speed stranding machine is (2~2.78) times that of the high-speed 630-type tubular stranding machine; (3.33~4.67) times that of the ordinary 630-type tubular stranding machine which really achieve highly productive and efficient.

Main Components

The equipment is mainly composed of pay-off device, wire inlet mold base, threading mold, stranding part (rack part, rotating part, twisting bow, transmission part, traction part, bobbin loading and unloading part, take-up and traversing device), transmission system , electrical control system, safety fence, etc.

1. Pay-off Device

Different pay-off types can be used according to customers’ needs, basket type pay-off or reel pay-off.

1) Basket coiler type pay-off

The basket type pay-off has the advantages of convenient change with no stop. Compared with reel type pay-off, it can not only save the time of changing the line, but also meet the requirements of large length and continuous production.

2) Reel type pay-off

Reel type active pay-off is suitable for occasions that require precise control of the pay-off tension which can automatically track the take-up speed and provide the constant tension required by the process. There are two types of reel-type active pay-off: dual-shaft active pay-off and single-shaft active pay-off. Among them, the dual-shaft active pay-off adopts a symmetrical, unidirectional outlet type on both sides. The max. pay-off speed can reach 300m/min.

The reel-type active pay-off adopts a shaftless pneumatic jack shaft, which is convenient for reel change. Pneumatic swing arm tension control, with displacement detection device, uniform and stable pay-off tension. The surface of the pay-off guide wheel is chrome-plated to reduce the possibility of wire core wear. It has wire broken detecting function, and a linked stranded wire host control system. When the wire is broken, it can automatically stop to avoid a large number of unqualified products.

2. The Stranding Part

Reel type active pay-off is suitable for occasions that require precise control of the pay-off tension which can automatically track the take-up speed and provide the constant tension required by the process. There are two types of reel-type active pay-off: dual-shaft active pay-off and single-shaft active pay-off. Among them, the dual-shaft active pay-off adopts a symmetrical, unidirectional outlet type on both sides. The max. pay-off speed can reach 300m/min.

The reel-type active pay-off adopts a shaftless pneumatic jack shaft, which is convenient for reel change. Pneumatic swing arm tension control, with displacement detection device, uniform and stable pay-off tension. The surface of the pay-off guide wheel is chrome-plated to reduce the possibility of wire core wear. It has wire broken detecting function, and a linked stranded wire host control system. When the wire is broken, it can automatically stop to avoid a large number of unqualified products.

FAQ

Q: Can I visit your factory?

A: All the customers from both home and abroad are warmly welcomed to visit our company and factory.

Q: Do you supply the installation and commissioning?

A: Yes, we do as followings:

-As soon as customer informed us the machines are put in the right place, we will send both mechanical and electrical engineer for machine start up.

-No-load testing: After machine installed completely, we make no-load testing first.

-With-load testing: Usually we will can produce 3 different wires to make load testing.

-Acceptance report: After the buyer confirms that machine can reach all specification under contract, the acceptance report will be signed for our record that machine will be in guarantee period.

Q: What information should I offer to get a detailed quotation from you?

A: For single machine: Usually we need to know inlet wire size, outlet wire size to be produced, productivity, pay off and take up size to choose the right machine.

For new cable plant or new cable production line, we need to know the datasheet of cables to be produced, the productivity, the standards to be followed, etc to design all machines needed.

Q: Can you supply the auxiliary equipment along with the machines?

A: Yes, definitely.

We has supplied heat exchanger, copper/aluminum powder filter machine, cooling tower, chiller, air compressor, drawing dies, pointing machine, cold welders, bobbins etc. with our machines.

Q: Could you do the design for the whole plant?

A: Yes, this is our advantage.

With the data sheet of cable to be produced, the standard your cables should follows, the productivity you expected. Our engineer on production technology and machinery will make design of production machines, test equipment, accessories like bobbins, dies, rewinding lines and materials needed.

Q: How can I know the status of my order?

A: We have our OA system on tracking the production.

For any of your request we can send photos and videos of your order, also we can use FACETIME to let you know the production.

Q: How do you work on the inspection before delivery?

A: We will make dynamic balance testing, levelness testing, noise testing, etc. during production.

After production finished, usually we make no-load running of each machine before delivery. Customers are welcomed to attend the inspection.

Q: What exhibitions will you attend, can we meet in the fair?

A: Dusseldorf International Wire and Cable Fair;

Wire South America Fair;

International Wire and Cable Fair in Shanghai;

International Istanbul Wire Fair, etc.

wire Southeast Asia Fair, etc.