Intelligent Warehousing

Product Details

Due to the low level of intelligence and the lack of scientific planning and management, for a long time, there has been such a phenomenon in the many traditional manufacturing enterprises warehouse, there is always a feeling that there are too many things in the warehouse but not enough, what you want can never be found, and unwanted things are not thrown away in time. As lacking of long-term planning, most of warehouse use manual management mode, which leads to inaccurate warehouse data, and managers cannot deal with shortages and explosions in a timely manner, which affects the normal production and operation of enterprises.

Intelligent warehousing is a warehousing management concept. It is a smart logistics realized through informatization, Internet of Things and mechatronics, thereby reducing warehousing costs, improving operational efficiency, and enhancing warehousing management capabilities. Intelligent warehousing is a link in the logistics process. The application of intelligent warehousing ensures the speed and accuracy of data input in all aspects, ensures that enterprises can grasp the real data of inventory in a timely and accurate manner, and reasonably maintain and control enterprise inventory.

LINTTOP can provide a complete set of intelligent warehousing and logistics software and hardware products and non-standard automation products such as intelligent forklift AGV, AGV dispatching system, automated storage control system, online visual inspection, etc., which have been successfully applied in wire&cable and other industries, effectively improving the logistics efficiency and intelligence level.

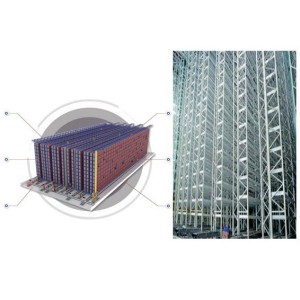

1. Stacked type three-dimensional warehouse

1)It is composed of high shelf, roadway stacker, conveyor, control systems and computer management systems (WMS), etc., which can complete the automatic storage and retrieval of unit goods under the control of the computer system.

2)It mainly stores materials carried by pallets and storage cages, and cooperates with peripheral conveying equipment, shuttle vehicle, AGV, etc. to complete the receipt and delivery.

3)Main common types are single depth telescopic forks, double depth telescopic forks, straight line, turning, track change , etc.

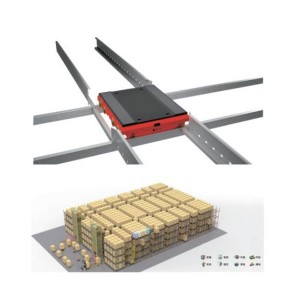

2. Shuttle intensive warehouse

1)The difference between shuttle intensive warehouse and traditional three-dimensional warehouse is that there is no roadway, so the storage density is increased by 30%. However, it also leads to the single inventory variety, low efficiency of warehousing, and difficulty in "FIFO". In terms of cost, shuttle intensive warehouse eliminates a large number of roadway stacker, and uses a small number of shuttle board with a slightly lower price, but the shelf cost increases.

2)Its common combination form adopts stacker or "shelf cart + hoist" to enter and exit the warehouse, and semi-automatic type is directly completed by a forklift, and the interior is equipped with shuttle racks and shuttle boards.

3. Four-way shuttle Intensive warehouse

Four-way shuttle car is an intelligent handling equipment that can realize both vertical and horizontal walking. The flexibility of the four-way shuttle car is very high, and the operation lane can be changed arbitrarily, and the capacity of the system can be adjusted by increasing or decreasing the number of shuttle car. When necessary, the scheduling by setting up an operation fleet can be used to respond to the peak of the system and solve the bottleneck of access and operation.

Four-way shuttle car can be replaced with each other. When a shuttle or hoist fails, other shuttles or hoists can be dispatched through the dispatching system to continue the operation without affecting the system capability.

Four-way shuttle car is not only suitable for low-flow and high-density storage, but also for high-flow and high-density storage. It can realize the maximization of efficiency, cost and resources.

4. Conveyor system

The conveying system is mainly to complete task of conveying materials.

5. Control system

(1) Warehouse Management Software(WMS )

It is mainly used to manage warehouse data, control the operation of equipment, provide safe and reliable information for enterprises, with real-time monitoring and other functions. It is an important system software in the enterprise warehousing industry.

(2) Advantages of warehouse management software (WMS)

1) Timely data collection, precise process management, fully automated and intelligent guidance, improve work efficiency.

2) Precise location management, comprehensive status monitoring, and make full use of limited warehouse space.

3) All-intelligent automatic allocation of upper and lower shelves according to first-in, first-out, avoiding human error.

4) Real-time and reasonable control and maintenance of inventory.

5) Through the automatic collection of batch information, the traceability of product production or sales process can be realized.

FAQ

Q: Can I visit your factory?

A: All the customers from both home and abroad are warmly welcomed to visit our company and factory.

Q: Do you supply the installation and commissioning?

A: Yes, we do as followings:

-As soon as customer informed us the machines are put in the right place, we will send both mechanical and electrical engineer for machine start up.

-No-load testing: After machine installed completely, we make no-load testing first.

-With-load testing: Usually we will can produce 3 different wires to make load testing.

-Acceptance report: After the buyer confirms that machine can reach all specification under contract, the acceptance report will be signed for our record that machine will be in guarantee period.

Q: What information should I offer to get a detailed quotation from you?

A: For single machine: Usually we need to know inlet wire size, outlet wire size to be produced, productivity, pay off and take up size to choose the right machine.

For new cable plant or new cable production line, we need to know the datasheet of cables to be produced, the productivity, the standards to be followed, etc to design all machines needed.

Q: Can you supply the auxiliary equipment along with the machines?

A: Yes, definitely.

We has supplied heat exchanger, copper/aluminum powder filter machine, cooling tower, chiller, air compressor, drawing dies, pointing machine, cold welders, bobbins etc. with our machines.

Q: Could you do the design for the whole plant?

A: Yes, this is our advantage.

With the data sheet of cable to be produced, the standard your cables should follows, the productivity you expected. Our engineer on production technology and machinery will make design of production machines, test equipment, accessories like bobbins, dies, rewinding lines and materials needed.

Q: How can I know the status of my order?

A: We have our OA system on tracking the production.

For any of your request we can send photos and videos of your order, also we can use FACETIME to let you know the production.

Q: How do you work on the inspection before delivery?

A: We will make dynamic balance testing, levelness testing, noise testing, etc. during production.

After production finished, usually we make no-load running of each machine before delivery. Customers are welcomed to attend the inspection.

Q: What exhibitions will you attend, can we meet in the fair?

A: Dusseldorf International Wire and Cable Fair;

Wire South America Fair;

International Wire and Cable Fair in Shanghai;

International Istanbul Wire Fair, etc.

wire Southeast Asia Fair, etc.