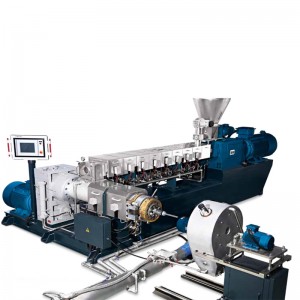

Tubular Stranding Machine

Product Details

1.Product information

Tubular stranding machine is an important equipment for wire and cable stranding. It is mainly used for stranding with back-twist of copper, aluminum, aluminum alloy stranded wires and steel-cored aluminum stranded wires, and can also be used for cabling of insulated wires.

The traditional tubular stranding machine generally adopts the ground shaft transmission. The transmission of the traction device and the cage is usually driven by the same motor through the reduction box, gearbox, ground shaft, angle box, etc. The take-up and traverser are individually or centralizedly driven and controlled by the above motors.

This structure has many disadvantages.

(1) The ground shaft transmission is an open drive, with poor lubrication conditions and easy entry of dust and other foreign objects, causing gear wear and damage, and loud production site noise.

(2) Gear shifting is adopted, and the gearbox structure is complex. The gap between the gears is large, which is prone to movement shock and damage to the ground shaft, gears, and boxes. At the same time, due to its complex mechanical structure, it is more difficult to maintain the whole machine.

(3) Due to the limitation of the ground shaft, the rotation speed of the cage is low, and the production speed is difficult to increase, which restricts the production efficiency of the production.

(4) Due to the fixed speed ratio of the gearbox, its pitch can only be changed within a limited range. It is impossible to choose the pitch required by some process designs.

The tubular stranding machine provided by LINT TOP integrates the stranding production process of the domestic first-class cable manufacturers, and at the same time absorbs the advantages of the same type of equipment abroad. It adopts the transmission method with individual motors, and each cage and capstan are driven by separate motors.

2. Features

(1) Each component is driven by a separate motor, with a simple structure and low operating noise.

(2) Integral welding of the bottom plate of the cage, and is processed by a CNC gantry boring and milling machine at one time, with high processing precision, which can ensure the high-speed operation of the equipment.

(3) The whole machine is managed by PLC and touch screen.

(4) The equipment is equipped with a variety of protections, such as fault alarm of the AC speed control device, overload protection of the take-up, air pressure under-voltage protection, automatic shutdown of the disconnection, etc., which are safe and reliable.

(5) Before the equipment leaves the factory, the high-precision dynamic balancing instrument will check the dynamic balance of the cage, so that the main engine runs at high speed and has a long service life.

Main main technical parameters below:

|

Model |

Single wire diameter (mm) |

Max. stranded outer diameter (mm) |

Stranding pitch (mm) |

Max. rotating speed (rpm) |

|

|

Copper wire |

Aluminum wire |

||||

|

630/1+6 |

1.8-4.6 |

2.0-5.0 |

15 |

36-200 |

500 |

|

630/12+1250/1 |

1.8-4.6 |

2.0-5.0 |

25 |

33.68-328.11 |

350 |

Main Components

It is mainly composed of central pay-off frame, cage, wire closing die holder, meter counter, double-wheel traction, end-shaft type take-up (or gantry type take-up), electrical control system, protective cover, etc.

1.(1) 630/1+6 tubular stranding machine

Both ends of the cylinder are supported by bearings, and the middle is supported by large bearings. It has the characteristics of stable operation, low noise and long service life. The cage is driven by a separate AC variable frequency motor and controlled by a frequency converter.

The large bearing in the middle of the cage is lubricated with thin oil, which is supplied by the thin oil station. It can fully lubricate and cool, and reduce environmental pollution.

The pay-off is an end-shaft structure, the spring automatically clamps the bobbin, the bobbin is released pneumatically. It has bobbin locking protection. Easy, fast and safe operation.

The tension of pay-off is controlled by mechanical friction, and the tension is adjusted manually.

The bottom plate of the cage is provided with a disconnection induction detection device along the axial direction of the cage.

The external wiring method is adopted, which is convenient for threading.

The cage brake adopts two sets of pneumatic butterfly brakes at the front and rear.

The protective cover adopts a semi-circular porous plate axial sliding door structure, which can be opened horizontally and has electrical safety protection.

2.(2)630/6+1250/1 tubular stranding machine

The stranding cage consists of a 12-disk cylinder and a 1250 bow stranded body. The two ends of the 12-disk cylinder are supported by bearings, the middle is supported by large-sized bearings, and the two ends of the bow stranded body are supported by bearings. The operation is stable, the noise is low, and the service life is long. The stranding cage is driven by a separate AC variable frequency motor and controlled by a frequency converter.

The internal bobbin frame is an end shaft structure, the spring automatically clamps the bobbin, the bobbin is released pneumatically. It has bobbin locking protection. The inner bobbin frame of the bow stranded body is an end shaft structure, the bobbin is manually clamped or released, and it has bobbin locking protection. Easy, fast and safe operation.

The tension of pay-off is controlled by mechanical friction, and the tension is adjusted manually.

The bottom plate of the cage is provided with a disconnection induction detection device along the axial direction of the cage.

The wiring of the cage adopts the external wiring method, and enters the paralleling die holder through the large twisting bow of the bow stranded body, and the wiring of the bowing body enters the paralleling die holder through the center hole of the support holder.

The cage brake adopts pneumatic butterfly brakes.

The protective cover of the cylinder body adopts a semicircular porous plate axial sliding door structure, and the protective cover of the bow strand adopts a house type axial sliding door structure. Horizontal push and pull to open, and electrical safety protection.

FAQ

Q: Can I visit your factory?

A: All the customers from both home and abroad are warmly welcomed to visit our company and factory.

Q: Do you supply the installation and commissioning?

A: Yes, we do as followings:

-As soon as customer informed us the machines are put in the right place, we will send both mechanical and electrical engineer for machine start up.

-No-load testing: After machine installed completely, we make no-load testing first.

-With-load testing: Usually we will can produce 3 different wires to make load testing.

-Acceptance report: After the buyer confirms that machine can reach all specification under contract, the acceptance report will be signed for our record that machine will be in guarantee period.

Q: What information should I offer to get a detailed quotation from you?

A: For single machine: Usually we need to know inlet wire size, outlet wire size to be produced, productivity, pay off and take up size to choose the right machine.

For new cable plant or new cable production line, we need to know the datasheet of cables to be produced, the productivity, the standards to be followed, etc to design all machines needed.

Q: Can you supply the auxiliary equipment along with the machines?

A: Yes, definitely.

We has supplied heat exchanger, copper/aluminum powder filter machine, cooling tower, chiller, air compressor, drawing dies, pointing machine, cold welders, bobbins etc. with our machines.

Q: Could you do the design for the whole plant?

A: Yes, this is our advantage.

With the data sheet of cable to be produced, the standard your cables should follows, the productivity you expected. Our engineer on production technology and machinery will make design of production machines, test equipment, accessories like bobbins, dies, rewinding lines and materials needed.

Q: How can I know the status of my order?

A: We have our OA system on tracking the production.

For any of your request we can send photos and videos of your order, also we can use FACETIME to let you know the production.

Q: How do you work on the inspection before delivery?

A: We will make dynamic balance testing, levelness testing, noise testing, etc. during production.

After production finished, usually we make no-load running of each machine before delivery. Customers are welcomed to attend the inspection.

Q: What exhibitions will you attend, can we meet in the fair?

A: Dusseldorf International Wire and Cable Fair;

Wire South America Fair;

International Wire and Cable Fair in Shanghai;

International Istanbul Wire Fair, etc.

wire Southeast Asia Fair, etc.