PVC Pelletizing Line

Product Details

1. Overview

PVC plastic is based on PVC resin, mixed and granulated with stabilisers, plasticisers, lubricants, fillers, colourants and special purpose additives.

PVC plastic has excellent mechanical properties, high voltage resistance and insulation resistance, and it is flame retardant, oil resistant, weather resistant, drug resistant and water resistant. In the wire and cable industry, it is mainly used for the insulation of low-voltage power cables, control cables, building wires, and the sheathing of various cables, etc. It is currently the most used plastic raw material in wire and cable products.

2. Process of PVC Pelletizing

PVC resin and various additives are made into plastic pellets through the following processes:

Weighing - Mixing - Extrusion - Pelletizing - Cutting

1. Weighing: Measured separately by main ingredient recipe, minor ingredient recipe and colour powder recipe;

2. Mixing: The weighed materials are prepared into a uniformly dispersed, easy-flowing powdery mixture for extrudering according to a certain feeding sequence and process.

3. Extrusion: The dry mixture will pass through a mixing device with shearing and extrusion functions, and is fused and plasticized for pelletizing.

4. Pelletizing: through the measurement, mixing, mixing and plasticizing the mixture into pellets.

5.Cutting: Cold cutting and hot cutting

(1) Cold cutting: Using water cooling commonly, cooling first and then cutting;

(2) Hot cutting: Using air cooling commonly, cutting first and then cooling.

3. PVC Pelletizing Line

We have rich experience in the field of pelletizing PVC compounds, and we can provide a complete set of pelletizing production lines with a variety of capacity requirements for you, including PVC compounds mixing and feeding system, PVC compounding, pelletizing and extruder system.

3.1 PVC compounds mixing and feeding system

We can provide two kinds of PVC compounds mixing and feeding system: Semi-automatic and full-automatic PVC mixing and feeding systems. The semi-automatic PVC mixing and feeding system is suitable for 25kg small bag feeding, and the full-automatic PVC compounding and feeding system is suitable for ton bag feeding.

1. Semi-automatic PVC mixing and feeding system

This system is a mixed conveying system for PVC pelletizing. The main raw materials applicable are PVC powder, CaCO3 powder, liquid and powder additives. For material feeding, the system feeds the main silo through an independent pipeline. The feeding end adopts manual feeding. The two main materials are measured by manual accumulation method, and the high-speed mixer is automatically fed.

The liquid material system is equipped with automatic weighing of three liquid raw materials. The maximum weighing range is 100kg. After the liquid raw material weighing is completed, the liquid is automatically added to the mixer by gravity within the set range according to the mixing process of the mixer.

2. Full-automatic PVC mixing and feeding system

The difference between this system and the semi-automatic PVC mixing and feeding system is: PVC and CaCO3 use ton bags, the materials are conveyed to the weighing vacuum hopper through vacuum negative pressure, the materials in the feeding station are fed by spirals, and the system feeds the main material through a separate pipeline. In order to meet the measurement accuracy requirements of the main material scale, the feeding end adopts a frequency-conversion speed-regulated screw feeder for feeding. The two main materials are measured by the accumulation method, and the feeding measurement control is carried out while conveying, and the measured materials are measured. Feeding the high-speed mixer automatically through program control.

3.2 Mixing, Pelletizing, Extruders for PVC

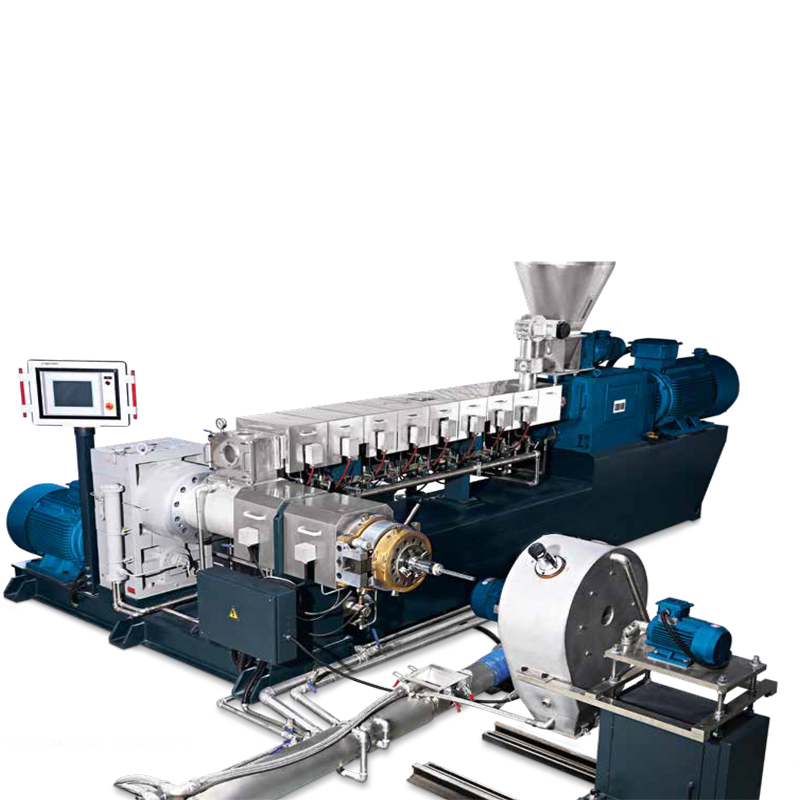

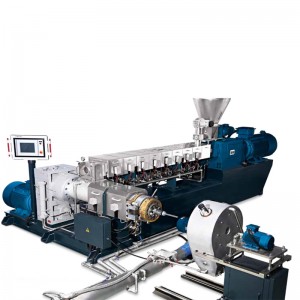

LT PLUS series two-stage mixing, pelletizing and extruder system is a cost-effective pelletizing extruders system for PVC provided by LINT TOP. High-precision processing and manufacturing provide customers with more cost-effective and effective solutions within the wide range of processing applications on the basis of ensuring high quality.

This system is mainly composed of feeding system, twin-screw extruder, single-screw extruder, screen changer, air-cooled die face cutting system, vibrating screen, etc.

The LT PLUS series two-stage mixing, pelletizing and extruder system is mainly used for the modification and mixing of heat-sensitive and shear-sensitive materials. The two-stage structure and the modular design of the processing section are suitable for high-efficient mixing various processing applications, such as PVC cable materials.

1. Working principle of LT PLUS Two-Stage:

1) Plasticizing, mixing and homogenizing in the twin screw process section;

2) Open, pressureless product transfer into the discharge screw with the possibility of degassing;

3) Gentle discharge through the die plate with a slow rotating single screw;

4) Air-cooling pelletizing as well as eccentric pelletizing-optionally available with strand and waterring pelletizing.

2. Control system

1) RELAY CONTROL: Simple, low-cost, but reliable and easy maintenance system;

2) PLC: Visualized touch screen to control the machine. Functions like supervision, alarm, print and parameter tendency can be included;

3) IPC: System with bus control technology (Profinet, Profibus, OPC, etc.). One PC to control several production lines,including functions like supervision, data collection and tendency analysis.

Technical Parameters

|

Model |

Screw diameter (mm) |

Max screw speed (rpm) |

Throughput(kg/h) |

|

|

LT PLUS 50-100 two-stage |

50 |

51 |

400/600 |

100~380 |

|

SE 100 |

100 |

60/85 |

||

|

LT PLUS 65-150 two-stage |

65 |

62 |

400/600 |

150~640 |

|

SE 150 |

150 |

60/85 |

||

|

LT PLUS 75-180 two-stage |

75 |

71 |

400/600 |

300~1100 |

|

SE 180 |

180 |

60/85 |

||

|

LT PLUS 96-200 two-stage |

96 |

94 |

400/600 |

600~2000 |

|

SE 200 |

200 |

60/85 |

Our Service

FAQ

Q: Can I visit your factory?

A: All the customers from both home and abroad are warmly welcomed to visit our company and factory.

Q: Do you supply the installation and commissioning?

A: Yes, we do as followings:

-As soon as customer informed us the machines are put in the right place, we will send both mechanical and electrical engineer for machine start up.

-No-load testing: After machine installed completely, we make no-load testing first.

-With-load testing: Usually we will can produce 3 different wires to make load testing.

-Acceptance report: After the buyer confirms that machine can reach all specification under contract, the acceptance report will be signed for our record that machine will be in guarantee period.

Q: What information should I offer to get a detailed quotation from you?

A: For single machine: Usually we need to know inlet wire size, outlet wire size to be produced, productivity, pay off and take up size to choose the right machine.

For new cable plant or new cable production line, we need to know the datasheet of cables to be produced, the productivity, the standards to be followed, etc to design all machines needed.

Q: Can you supply the auxiliary equipment along with the machines?

A: Yes, definitely.

We has supplied heat exchanger, copper/aluminum powder filter machine, cooling tower, chiller, air compressor, drawing dies, pointing machine, cold welders, bobbins etc. with our machines.

Q: Could you do the design for the whole plant?

A: Yes, this is our advantage.

With the data sheet of cable to be produced, the standard your cables should follows, the productivity you expected. Our engineer on production technology and machinery will make design of production machines, test equipment, accessories like bobbins, dies, rewinding lines and materials needed.

Q: How can I know the status of my order?

A: We have our OA system on tracking the production.

For any of your request we can send photos and videos of your order, also we can use FACETIME to let you know the production.

Q: How do you work on the inspection before delivery?

A: We will make dynamic balance testing, levelness testing, noise testing, etc. during production.

After production finished, usually we make no-load running of each machine before delivery. Customers are welcomed to attend the inspection.

Q: What exhibitions will you attend, can we meet in the fair?

A: Dusseldorf International Wire and Cable Fair;

Wire South America Fair;

International Wire and Cable Fair in Shanghai;

International Istanbul Wire Fair, etc.

wire Southeast Asia Fair, etc.