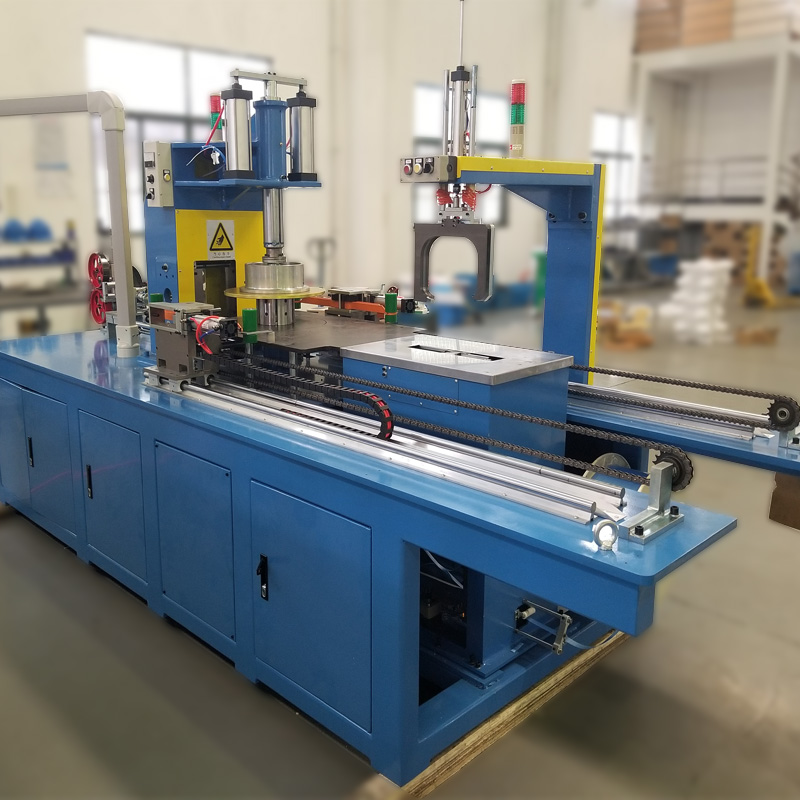

Wire Coiling Machine - Manufacturers, Suppliers, Factory from China

Our aim is usually to give superior quality items at aggressive rates, and top-notch company to clients around the earth. We have been ISO9001, CE, and GS certified and strictly adhere to their good quality specifications for Wire Coiling Machine, Wire Granulator For Sale, Types Of Drawing Lines, Aluminum Continuous Casting,Ftth Production Line. First company, we understand each other. Further more company, the trust is getting there. Our enterprise normally at your provider anytime. The product will supply to all over the world, such as Europe, America, Australia,Egypt, Hungary,South Korea, Cancun.Our faith is to be honest first, so we just supply high quality products to our customers. Really hope that we can be business partners. We believe that we can establish long time business relationship with each other. You can contact us freely for more information and pricelist of our products ! You will be Unique with our hair products !!

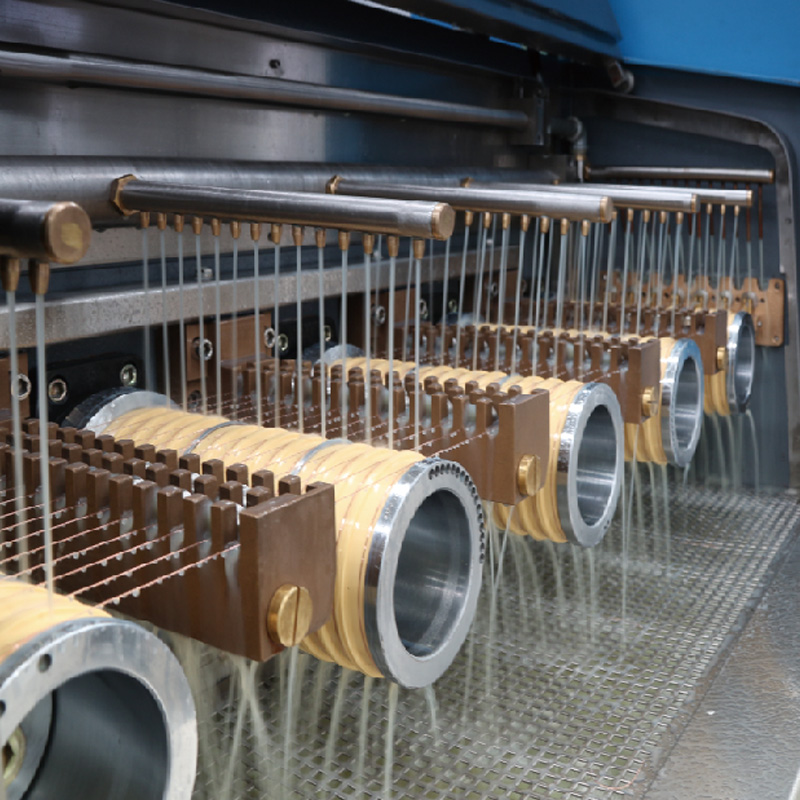

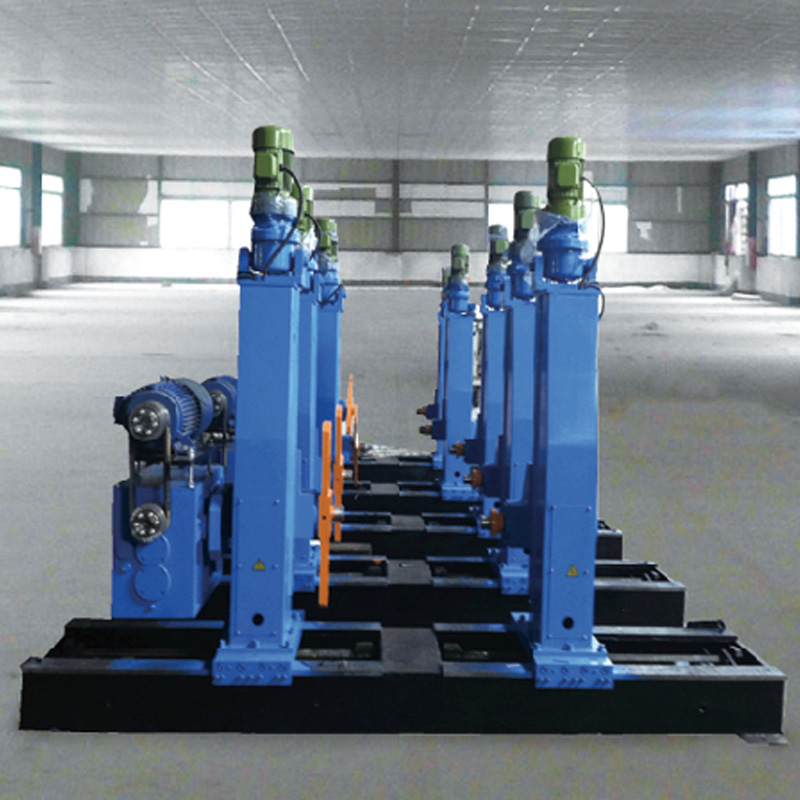

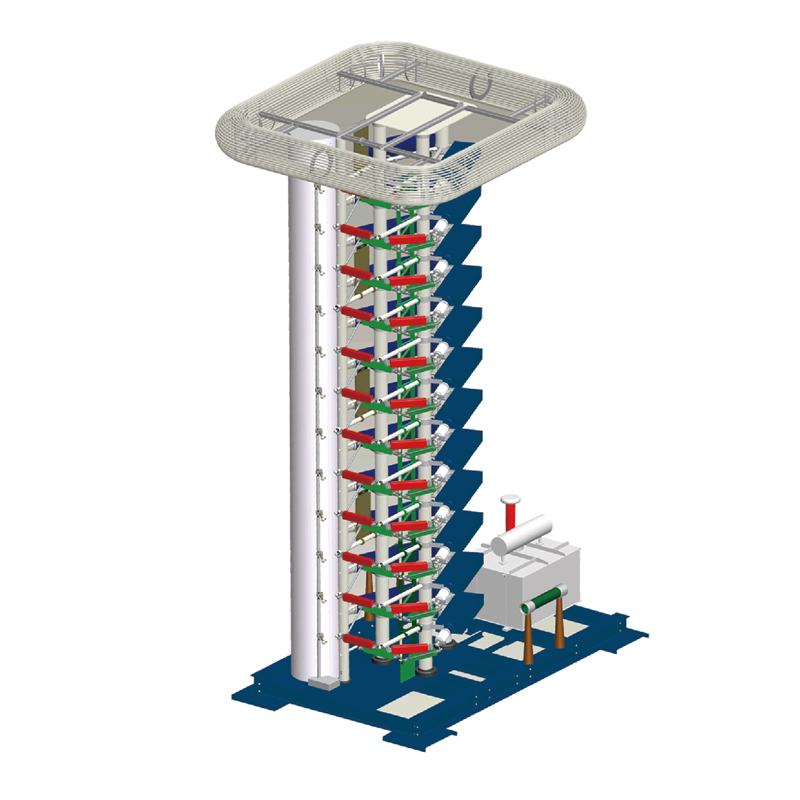

Related Products