Braiding Machine

Product Details

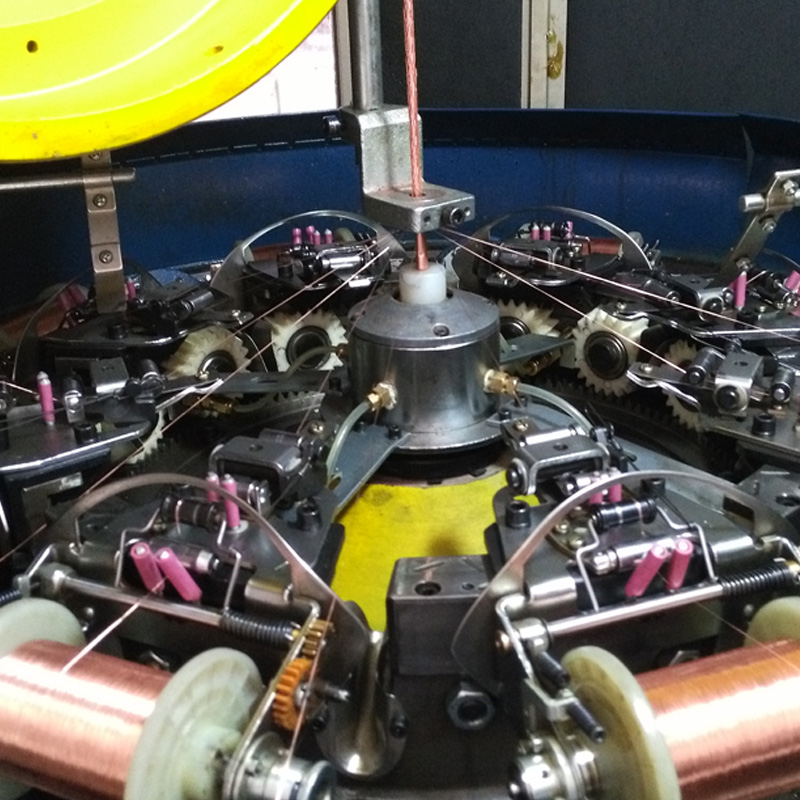

Braiding machine is a device used for the production of braiding wire and cable shield or armor. According to different product requirements, it can be used for braiding copper wire, tinned copper wire, silver plated copper wire, aluminum magnesium alloy wire, steel wire and other materials. It is suitable for the braiding of control cables, radio frequency cables, data cables, marine cables, mining cables and other products.

Our company has many years of experience in the development and production of braiding machines. We have developed various series of braiding machines such as vertical high-speed braiding machines, heavy vertical braiding machines, heavy horizontal braiding machines, etc. Each series include braiding machine with multiple spindles. The unique structural design, superb mechanical processing level and precise automatic control make the weaving machine developed by us have fast weaving speed, high weaving precision, large capacity of spindle, small fluctuation of weaving tension, stable operation, low energy consumption, Low noise and simple and convenient operation and maintenance. Compared with traditional low-speed weaving machines, production efficiency can be more than doubled.

The series of high-speed braiding machines developed by our company belong to the domestic first-class level, which can meet the braiding production of various wire and cable products.

1. Features

1. Humanized design of the whole machine, simple and convenient operation. Adopting frequency conversion control method with touch screen and PLC, automatic control, man-machine interface and servo motor drive. The production status is visible on the touch screen. Using man-machine dialogue to query, adjust and control, the braiding precision is greatly improved and the worker's operation difficulty is reduced. .

2. The advanced technology of quantitative and timed automatic lubrication can automatically supply oil to the equipment at the set time interval, so that the equipment can be well lubricated during high-speed operation.

3. Comprehensive fault and safety alarm warning system. It can realize the stop of broken wire, stop of finished wire and tension detection device, which guarantees the quality of braiding.

2. Braiding Effect

3. Main Technical Parameters

The main technical parameters of the equipment are as follows:

|

Item |

Vertical high speed braiding machine |

Vertical heavy high speed braiding machine |

Horizontal heavy high speed braiding machine |

|||||

|

Model |

LT-16A |

LT-24A |

LT-16Z |

LT-24Z |

LT-24W |

LT-32W |

LT-36W |

LT-48W |

|

Braiding form |

2 over 2 |

2 over 2 |

2 over 2 |

|||||

|

Braiding direction |

Vertical |

Vertical |

Horizontal |

|||||

|

No. Of spindles |

16 |

24 |

16 |

24 |

24 |

32 |

36 |

48 |

|

Bobbin size (mm) |

φ75*φ22*φ70 or φ80*φ22*φ80 |

φ110*φ45*φ100 |

φ110*φ45*φ100 |

|||||

|

Rotation speed (rpm) |

Max.150 |

Max.100 |

Max.70 |

Max.60 |

Max.45 |

Max.32 |

Max.30 |

Max.22 |

|

Braiding pitch length (mm) |

3.2~32.5 or 6.4~65 |

13.3~134.5 |

18.4~185.9 |

27~270 |

27~270 |

36~360 |

||

|

Maximum braiding outer diameter (mm) |

14 |

24 |

30 |

45 |

60 |

75 |

90 |

120 |

|

Usage |

Mainly suitable for soft shield braiding form including copper wires, aluminum-magnesium alloy wires and other materials for small-size communication cables and control cables |

Mainly suitable for copper wire and steel wire braiding of large wire diameter control cables, marine cables, mining cables, etc. |

Mainly suitable for copper wires and steel wires braiding of large wire diameter marine cables and mining cables. |

|||||

In addition to high-speed braiding machines, our company can also provide medium-speed braiding machines for braiding copper ribbons and fiber material braiding machines.

Main Components

The braiding machine is mainly composed of pay-off, braiding unit, traction device, take-up, electromechanical control system, etc.

1. Braiding Unit

The braiding unit is the main component of the braiding equipment. It is driven by transmission shaft which is driven by a frequency conversion motor through a synchronous belt. The transmission shaft is further driven by two synchronous belts to rotate the rotary table and the ring gear, while the other synchronous belt drives the traction disk through the worm gear and the variable-speed hanging wheel.

The pay-off tension of the braided spindles can be adjusted according to the diameter of the braided single wire and the braided wire material, the tension is sensitive, easy to adjust, the pay-off is stable, the braiding quality is high, and the wire capacity is large.

The braiding unit is equipped with a broken wire alarm device, which can automatically stop when the braided wire is broken, broken or no-wires, and the action is sensitive; the wire threading nozzle of each wire wheel is smooth and wear-resistant, and there is no problem of stuck or wire clamping.

Adopting advanced anti-noise system, the equipment has low noise during operation, which effectively reduces noise pollution at the production site.

2. Traction Device

The traction device of the 16-spindle, 24-spindle vertical high-speed braiding machine and heavy-duty vertical braiding machine is a traction wheel, which is driven by the main drive shaft through a set of gears, variable-speed hanging wheels, and worm gears.

The traction device of the 24-spindle, 32-spindle, 36-spindle, and 48-spindle heavy-duty horizontal braiding machine is caterpillar traction, which is installed in front of the braiding machine, and the traction output shaft is driven by the sprocket at one end of the transmission shaft through the chain to realize the synchronization of traction Spin. The other end of the traction output shaft is equipped with a set of pitch-hanging wheel sets, and different combinations of hanging-wheels can be selected to obtain the required knitting pitch.

Auxiliary Equipment

1. Doubling Winder

The doubling winder is a special equipment for the doubling process before braiding. The doubling machine developed by us adopts variable-frequency control way, which can realize stepless speed variation, and has functions of breaking wires and fault protection. It has characteristics of fast doubling, neat cable arrangement, stable tension and so on.

The pay-off stand matched with the doubling machine has functions of tension control and automatic breaking of wire. It is divided into passive, active and static type according to the diameter of the doubling wires.

The main technical parameters of doubling winder are as follows:

|

Model |

LT-5 |

LT-6 |

|

No. of doubling threads |

2~3 |

2~3 |

|

Max. Rotation speed (rpm) |

2800 |

2800 |

|

No. Of wires in each thread (wires) |

1~10 |

1~10 |

|

Suitable single wire diameter (mm) |

0.05~0.12 |

0.12~0.40 |

2. Full-automatic Rewinding Machine

We also provide the other type of rewinding machine which is a new type of full-automatic rewinding machine, please click: Full-automatic Rewinding Machine

Installation and Commissioning

After the order established, we will send the layout drawing and foundation drawing to our customers, as well as an operation manual. The customer can first arrange the plant according to the drawings and prepare the materials needed for starting. Once the engineer arrives at the scene, he will have a meeting with the customer to discuss the commissioning plan and estimated commissioning time. During the commissioning process, engineers will train workers in real time until they master the skills, and both parties will sign an acceptance report on the braiding machine.

FAQ

Q: Can I visit your factory?

A: All the customers from both home and abroad are warmly welcomed to visit our company and factory.

Q: Do you supply the installation and commissioning?

A: Yes, we do as followings:

-As soon as customer informed us the machines are put in the right place, we will send both mechanical and electrical engineer for machine start up.

-No-load testing: After machine installed completely, we make no-load testing first.

-With-load testing: Usually we will can produce 3 different wires to make load testing.

-Acceptance report: After the buyer confirms that machine can reach all specification under contract, the acceptance report will be signed for our record that machine will be in guarantee period.

Q: What information should I offer to get a detailed quotation from you?

A: For single machine: Usually we need to know inlet wire size, outlet wire size to be produced, productivity, pay off and take up size to choose the right machine.

For new cable plant or new cable production line, we need to know the datasheet of cables to be produced, the productivity, the standards to be followed, etc to design all machines needed.

Q: Can you supply the auxiliary equipment along with the machines?

A: Yes, definitely.

We has supplied heat exchanger, copper/aluminum powder filter machine, cooling tower, chiller, air compressor, drawing dies, pointing machine, cold welders, bobbins etc. with our machines.

Q: Could you do the design for the whole plant?

A: Yes, this is our advantage.

With the data sheet of cable to be produced, the standard your cables should follows, the productivity you expected. Our engineer on production technology and machinery will make design of production machines, test equipment, accessories like bobbins, dies, rewinding lines and materials needed.

Q: How can I know the status of my order?

A: We have our OA system on tracking the production.

For any of your request we can send photos and videos of your order, also we can use FACETIME to let you know the production.

Q: How do you work on the inspection before delivery?

A: We will make dynamic balance testing, levelness testing, noise testing, etc. during production.

After production finished, usually we make no-load running of each machine before delivery. Customers are welcomed to attend the inspection.

Q: What exhibitions will you attend, can we meet in the fair?

A: Dusseldorf International Wire and Cable Fair;

Wire South America Fair;

International Wire and Cable Fair in Shanghai;

International Istanbul Wire Fair, etc.

wire Southeast Asia Fair, etc.