Copper Recycling Machine - Manufacturers, Suppliers, Factory from China

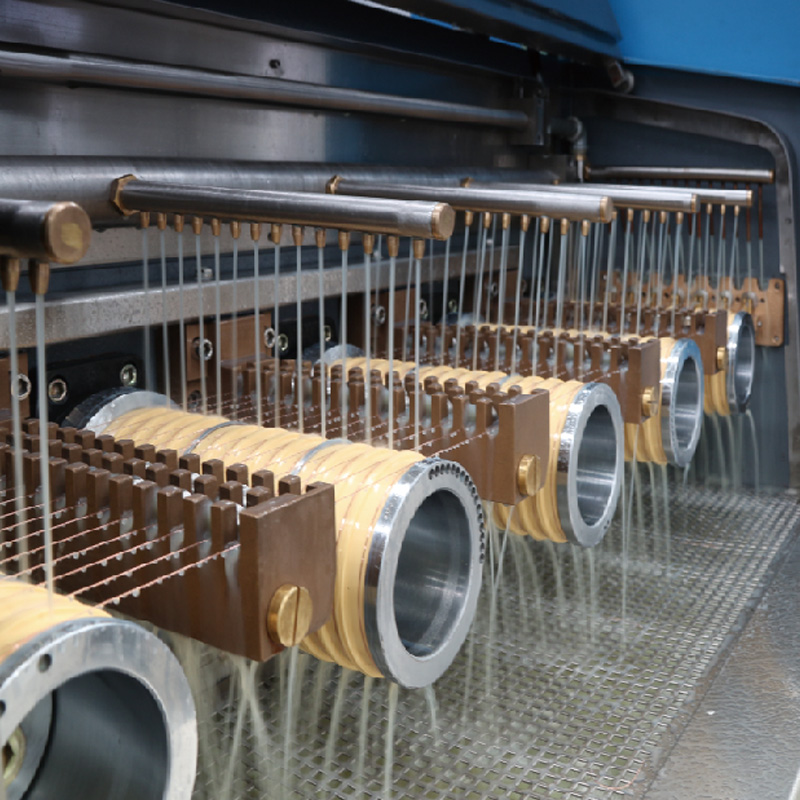

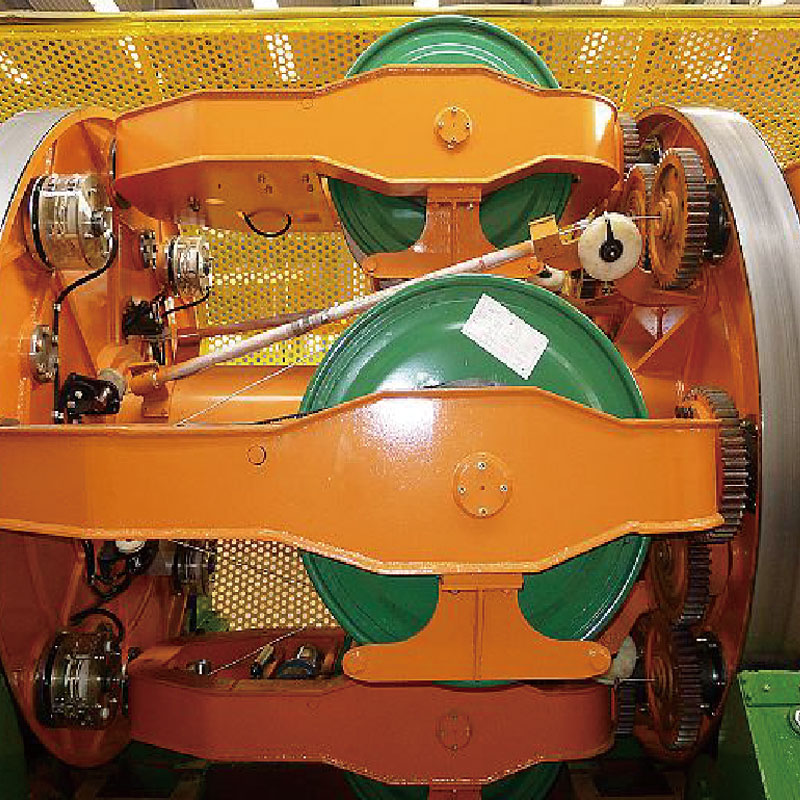

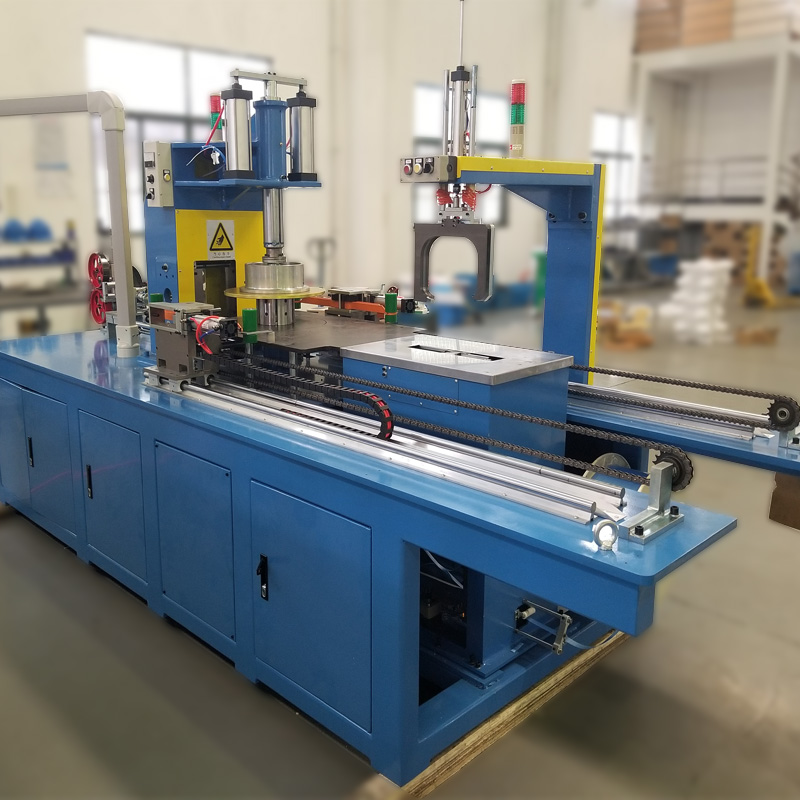

To constantly improve the management system by virtue of the rule of "sincerely, good faith and quality are the base of enterprise development", we widely absorb the essence of related products internationally, and constantly develop new products to meet the demands of customers for Copper Recycling Machine, Fine Wire Drawing Machine, Automatic Cable Coil Spool Shrink Wrap Machine, Rewinding Equipment,Aluminum Profile Aging Oven. Good quality, timely service and Competitive price, all win us a good fame in xxx field despite the international intense competition. The product will supply to all over the world, such as Europe, America, Australia,Thailand, venezuela,Finland, Senegal.In order to meet the increasing requirement of customers both home and aboard, we will keep carrying forward the enterprise spirit of "Quality, Creativity, Efficiency and Credit" and strive to top the current trend and lead fashion. We warmly welcome you to visit our company and make cooperation.

Related Products