Take Up Stand - China Manufacturers, Factory, Suppliers

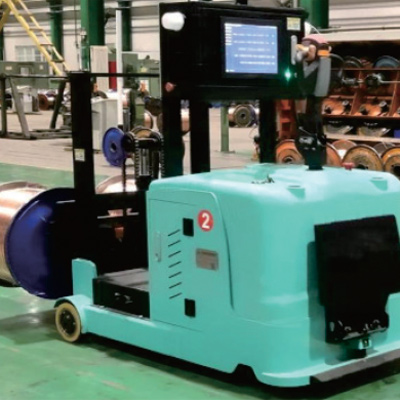

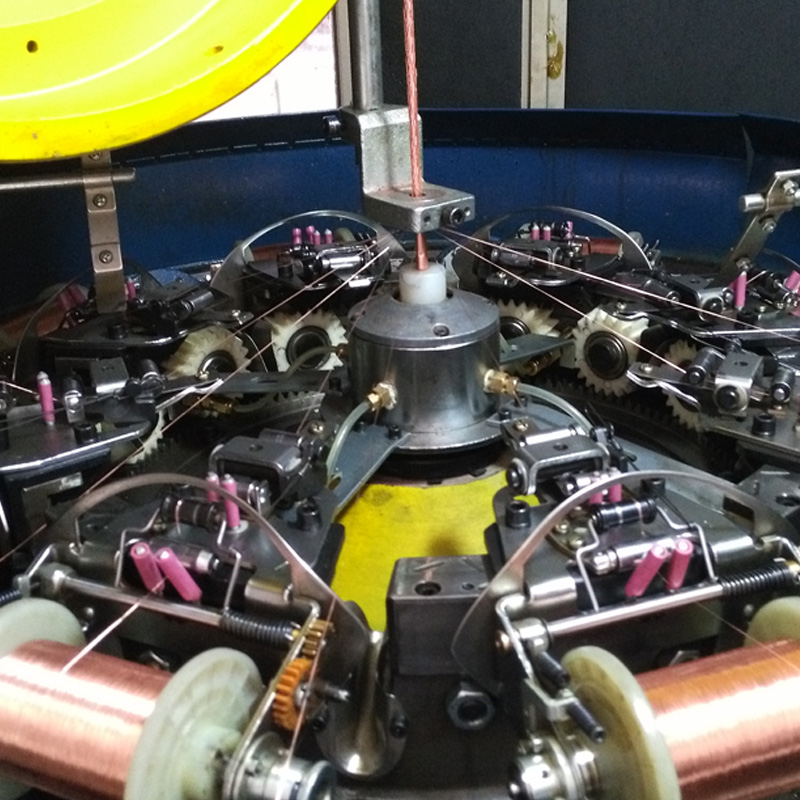

"Quality first, Honesty as base, Sincere service and mutual profit" is our idea, in order to develop continuously and pursue the excellence for Take Up Stand, Copper Wire Drawing Machine, Mica Taping Machine, Braided Wiring,Rewinding/Winding Equipment. The principle of our company is to provide high-quality products, professional service, and honest communication. Welcome all friends to place trial order for creating a long-term business relationship. The product will supply to all over the world, such as Europe, America, Australia,Madrid, Amman,Iran, Austria.We always stick to the tenet of "sincerity, high quality, high efficiency, innovation". With years of efforts, we have established friendly and stable business relationships with worldwide customers. We welcome any of your inquiries and concerns for our products, and we are sure that we will offer just what you want, as we always believe that your satisfaction is our success.

Related Products