Fine Wire Drawing Machine

Product Details

In order to meet the requirements for drawing copper wires with smaller specifications, our company has carefully developed and designed a high-speed drawing machine, which is suitable for drawing copper wires with smaller specifications.

1. Equipment Features

The drawing tower wheel adopts a double-layer arrangement design with novel structure, effectively reducing equipment footprint;

All the tower wheels, counting wheels, wire guide wheel and traversing guide wheel are sprayed with ceramic, which effectively increases the service life of the equipment;

2. Main Technical Parameters

The main technical parameters are as follows:

|

Model |

LT-22 |

LT-24 |

LTD-16 |

LTD-22 |

LTD-24 |

|

Inlet diameter (mm) |

0.70~1.20 |

0.40~1.20 |

0.80~2.0 |

0.70~1.60 |

0.70~1.60 |

|

Outlet diameter (mm) |

0.10~0.32 |

0.10~0.32 |

0.30~0.80 |

0.15~0.60 |

0.15~0.60 |

|

Mechanical speed (m / min) |

Max.2400 |

Max.2400 |

Max.2000 |

Max.2000 |

Max.2000 |

|

Tower wheel dia. (mm) |

190 |

190 |

200 |

190 |

190 |

|

Fixed speed wheel dia. (mm) |

150 |

150 |

200 |

200 |

200 |

|

Number of dies |

Max.22 |

Max.24 |

Max.16 |

Max.22 |

Max.24 |

|

Mechanical elongation (%) |

Sizing die: 15% Other: 17.6% |

Sizing die: 13% Other: 17.6% |

Sizing die: 15% Other: 17.6% |

Sizing die: 15% Other: 17.6% |

Sizing die: 13% Other: 8% |

|

Annealing current (A) |

Max.240 |

Max.240 |

Max.800 |

Max.500 |

Max.500 |

3. The Drawing Effect

The copper fine wire drawing machine has the characteristics of small equipment footprint, high production efficiency, and low operating noise. It not only improves the production efficiency of wire drawing, but also simplifies the production process. It is currently the leading fine wire drawing production line in China.

Main Components

This equipment is mainly composed of pay-off, drawing machine, annealing machine, tension controller, take-up and electric control system.

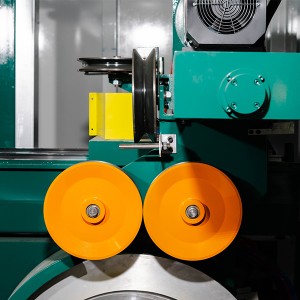

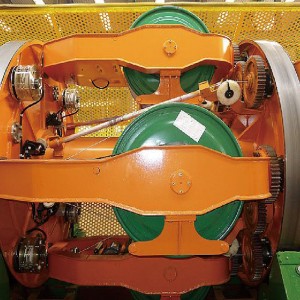

1. Wire Drawing Machine

The drawing tower wheel adopts a double-layer arrangement design, which is driven by a main motor through 4 belt shafts and the take-up shaft through a flat belt; the round copper wire enters the drawing host through the pay-off frame, and is drawn through the tower wheel and drawing dies. When drawing, the cooling method of wire and mold is spray type. The wire passes through the take-in wheel, the counting guide wheel, the tension rocker guide wheel, the thread guide wheel, and the cable guide wheel, and enters the take-up reel. The whole machine is designed with ergonomic principles, the structure is reasonable and reliable, and the operation is convenient.

2. Annealing Machine

The annealing adopts the contact short-circuit annealing principle, and the annealing machine uses a DC controller to track the take-up speed to control, ensuring that the wire is fully annealed when it is started and stopped. The annealing machine consists of a conductive system, an oxidation protection system, a cooling system, a drying system, and an electrical system. The oxidation protection method adopts steam protection; the cooling and lubrication adopts the drawing fluid with a concentration of 0.5% to 1%. Generally, cooling is provided by setting a pool or an external heat exchanger; the drying system uses compressed air and dies to dry. It can ensure that the appearance of the annealed copper wire is bright and free of oxidation, and can also meet the performance requirements of the elongation and resistivity of the annealed copper wire.

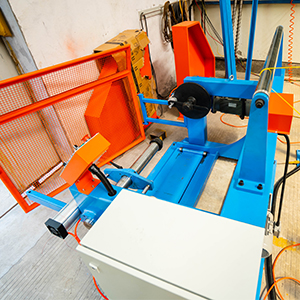

3. Take-up

The take-up adopts PND 400 high-speed wire take-up machine, which is suitable for the take-up of high-speed wire drawing machine. According to customer requirements, single or double reels can be selected, suitable for PND400 or PND300 reel. The clamping, lifting and braking of the reels are all pneumatic. The traversing system is driven by an independent motor and switched by a screw rod clutch. The braking system of the winding part adopts pneumatic brakes. When a disconnection occurs during operation or an emergency stop is performed, an emergency stop is performed immediately, quickly and promptly. Brake the reel to prevent damage to the wire and ensure safe operation.

Auxiliary Equipment

In addition to the above-mentioned devices such as pay-off, drawing machine, annealing machine, tension controller, take-up and electric control system, the wire drawing line also needs the drawing dies, copper powder filter, pointing machine, cold welder and other auxiliary equipment.

The auxiliary equipment from us can meet the wire drawing production of different types, which can not only ensure the smooth production process, improve the surface quality of products, but also reduce the loss of wire drawing equipment and increase the service life which are essential equipment in the production process.

Installation and Commissioning

We will send a preparation list after the equipment shipped on borad. In order for the installation and commissioning to proceed smoothly, customer can prepare materials according to the list we provided.

When the equipment is about to be completed, the two parties will communicate in detail on the commissioning plan. Customer should get all the things ready before our engineer arrives. After the engineer arrives at the scene, he will meet with the customer to communicate the commissioning plan, the required expenditure and the estimated completion time. After the installation finished, the engineer will start the equipment with no-load test and full-load test. During the drawing, the engineer will train the customer ’s workers, and at the same time, the engineer will also tell them the problems they often encounter in the process and the effective solutions. We will try our best to support the workers be familiar with the entire production line.

FAQ

Q: Can I visit your factory?

A: All the customers from both home and abroad are warmly welcomed to visit our company and factory.

Q: Do you supply the installation and commissioning?

A: Yes, we do as followings:

-As soon as customer informed us the machines are put in the right place, we will send both mechanical and electrical engineer for machine start up.

-No-load testing: After machine installed completely, we make no-load testing first.

-With-load testing: Usually we will can produce 3 different wires to make load testing.

-Acceptance report: After the buyer confirms that machine can reach all specification under contract, the acceptance report will be signed for our record that machine will be in guarantee period.

Q: What information should I offer to get a detailed quotation from you?

A: For single machine: Usually we need to know inlet wire size, outlet wire size to be produced, productivity, pay off and take up size to choose the right machine.

For new cable plant or new cable production line, we need to know the datasheet of cables to be produced, the productivity, the standards to be followed, etc to design all machines needed.

Q: Can you supply the auxiliary equipment along with the machines?

A: Yes, definitely.

We has supplied heat exchanger, copper/aluminum powder filter machine, cooling tower, chiller, air compressor, drawing dies, pointing machine, cold welders, bobbins etc. with our machines.

Q: Could you do the design for the whole plant?

A: Yes, this is our advantage.

With the data sheet of cable to be produced, the standard your cables should follows, the productivity you expected. Our engineer on production technology and machinery will make design of production machines, test equipment, accessories like bobbins, dies, rewinding lines and materials needed.

Q: How can I know the status of my order?

A: We have our OA system on tracking the production.

For any of your request we can send photos and videos of your order, also we can use FACETIME to let you know the production.

Q: How do you work on the inspection before delivery?

A: We will make dynamic balance testing, levelness testing, noise testing, etc. during production.

After production finished, usually we make no-load running of each machine before delivery. Customers are welcomed to attend the inspection.

Q: What exhibitions will you attend, can we meet in the fair?

A: Dusseldorf International Wire and Cable Fair;

Wire South America Fair;

International Wire and Cable Fair in Shanghai;

International Istanbul Wire Fair, etc.

wire Southeast Asia Fair, etc.