Strander Machine - China Manufacturers, Factory, Suppliers

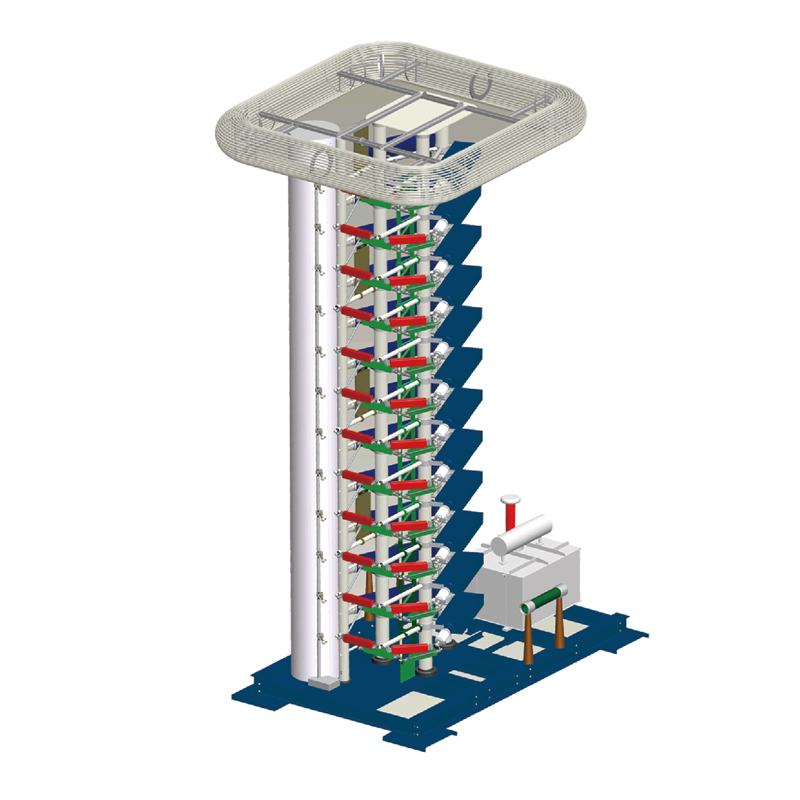

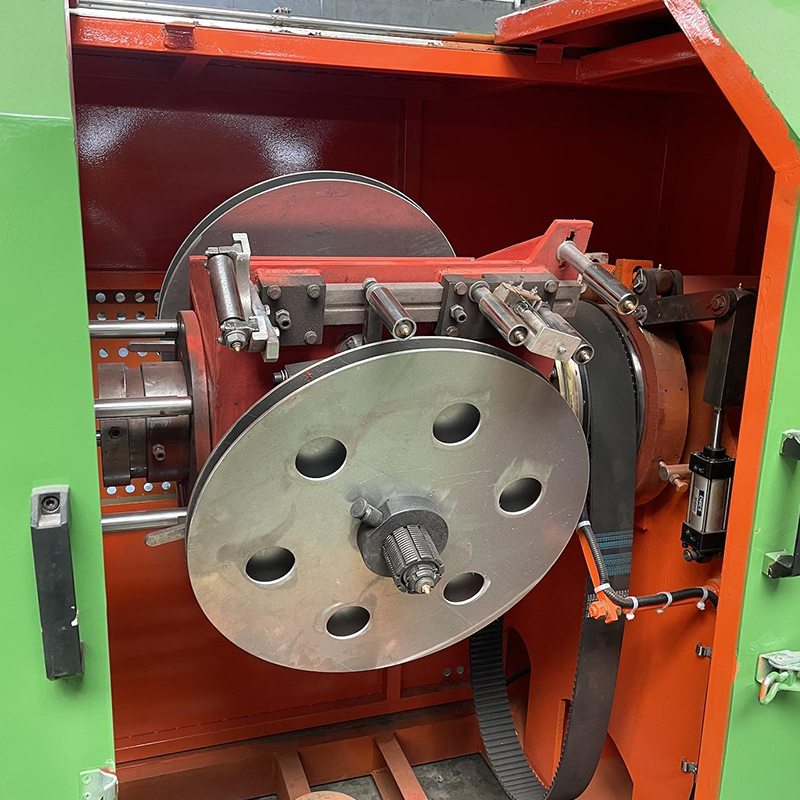

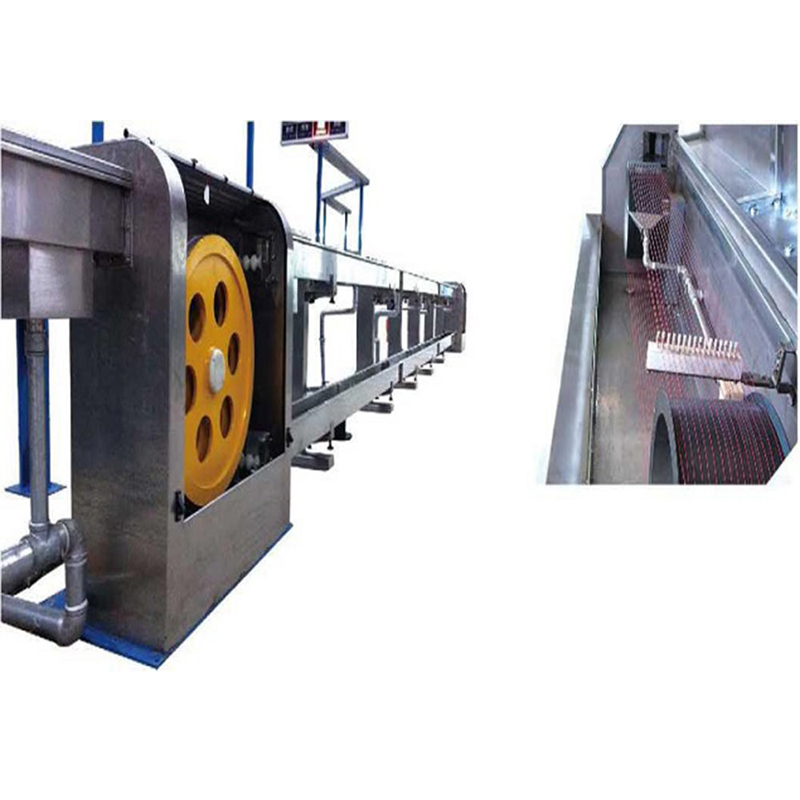

We always continually provide you with the most conscientious customer service, and the widest variety of designs and styles with finest materials. These efforts include the availability of customized designs with speed and dispatch for Strander Machine, Wire Drawing Line, Wire Bunching Machine, Vertical Wire Drawing Machine,Reel Winder Machine. We are not satisfied with the present achievements but we are trying best to innovate to meet buyer's more personalized needs. No matter where you are from, we are here to wait for your kind request, and welcom to visit our factory. Choose us, you can meet your reliable supplier. The product will supply to all over the world, such as Europe, America, Australia,Burundi, United Arab Emirates,Kuala Lumpur, France.We have established long-term, stable and good business relationships with many manufacturers and wholesalers around the world. Currently, we are looking forward to even greater cooperation with overseas customers based on mutual benefits. Please feel free to contact us for more details.

Related Products