Cable Packing Machine - China Manufacturers, Suppliers, Factory

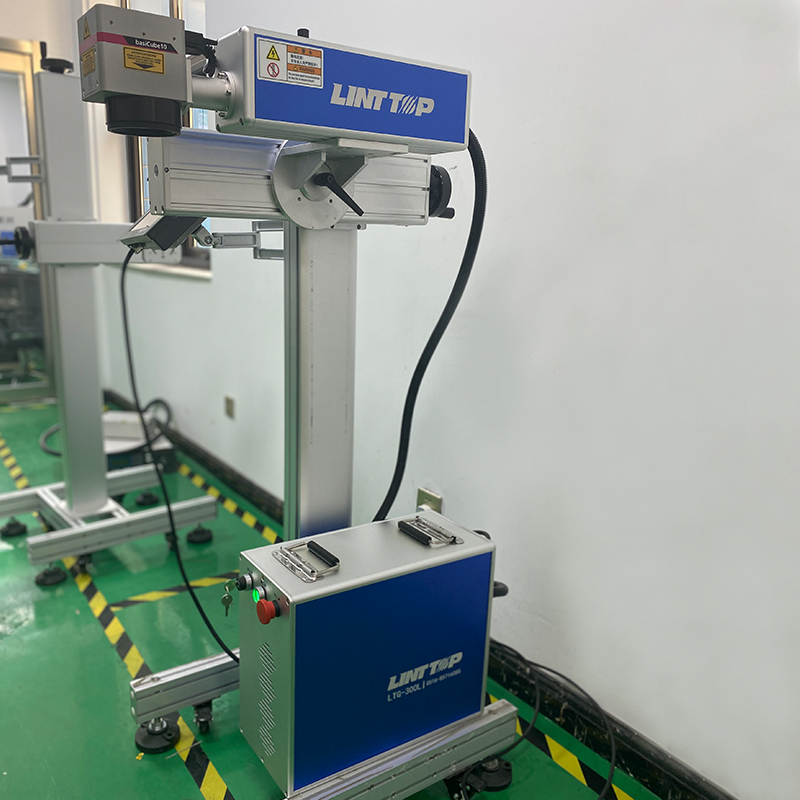

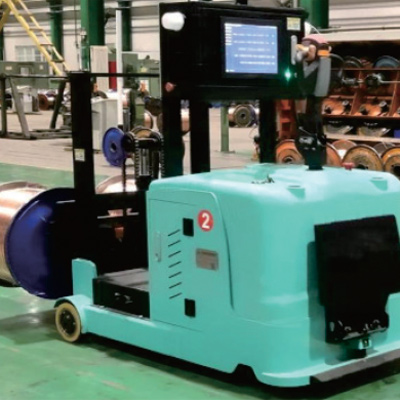

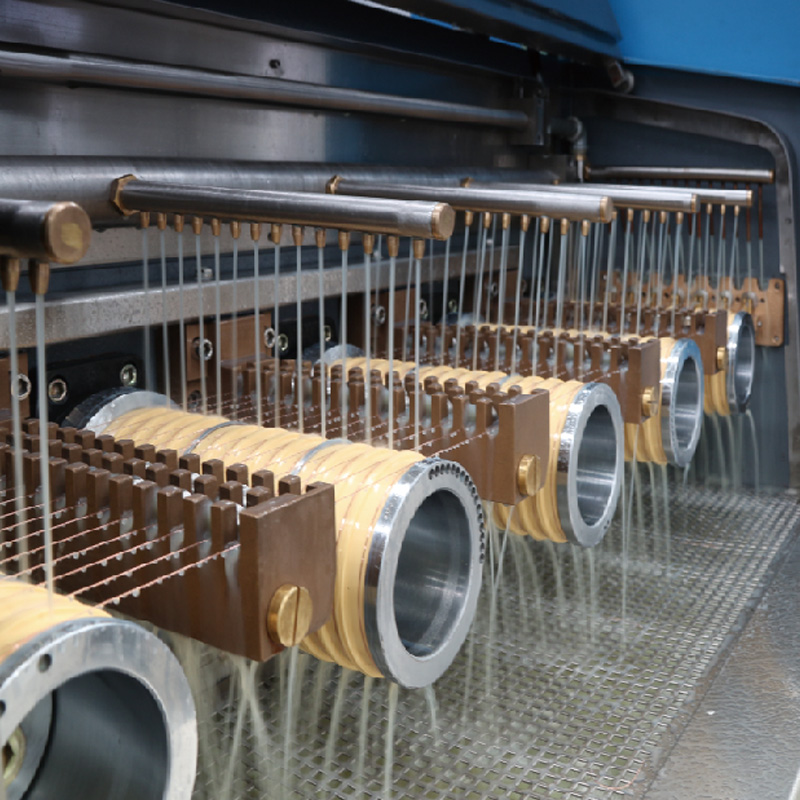

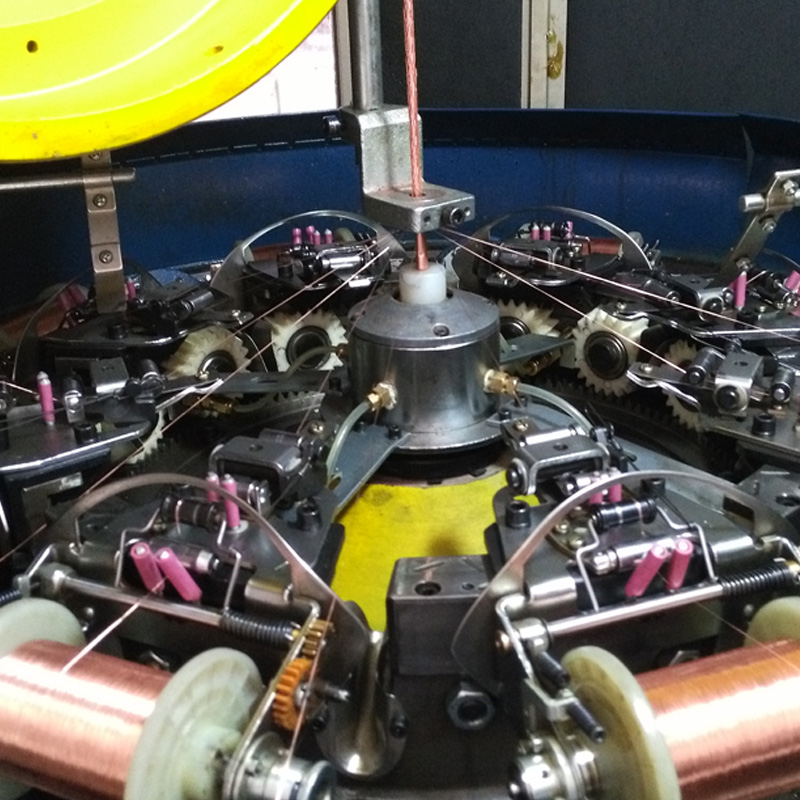

We constantly think and practice corresponding to the change of circumstance, and grow up. We aim at the achievement of a richer mind and body along with the living for Cable Packing Machine, Braid Machine, Rigid Machine, Wire Drawing Machinery,Copper Wire Shredder. To provide customers with excellent equipment and services, and constantly develop new machine is our company's business objectives. We look forward to your cooperation. The product will supply to all over the world, such as Europe, America, Australia,Serbia, Philadelphia,United Arab emirates, Salt Lake City.we always keep our credit and mutual benefit to our client, insist our high quality service to moving our clients. always welcome the our friends and clients to come and visit our company and guid our business, if you are interested in our products, you can also submit your purchase information online, and we will contact you immediately, we keep our highly sincere cooperation and wish everything in your side are all well.

Related Products