Rewinding/Winding Equipment - Manufacturers, Factory, Suppliers from China

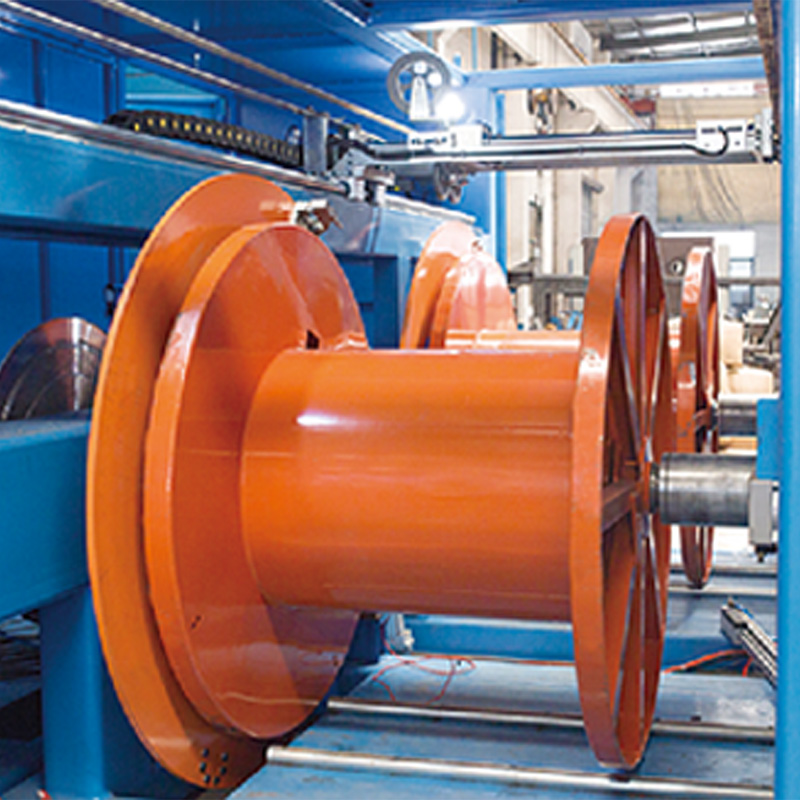

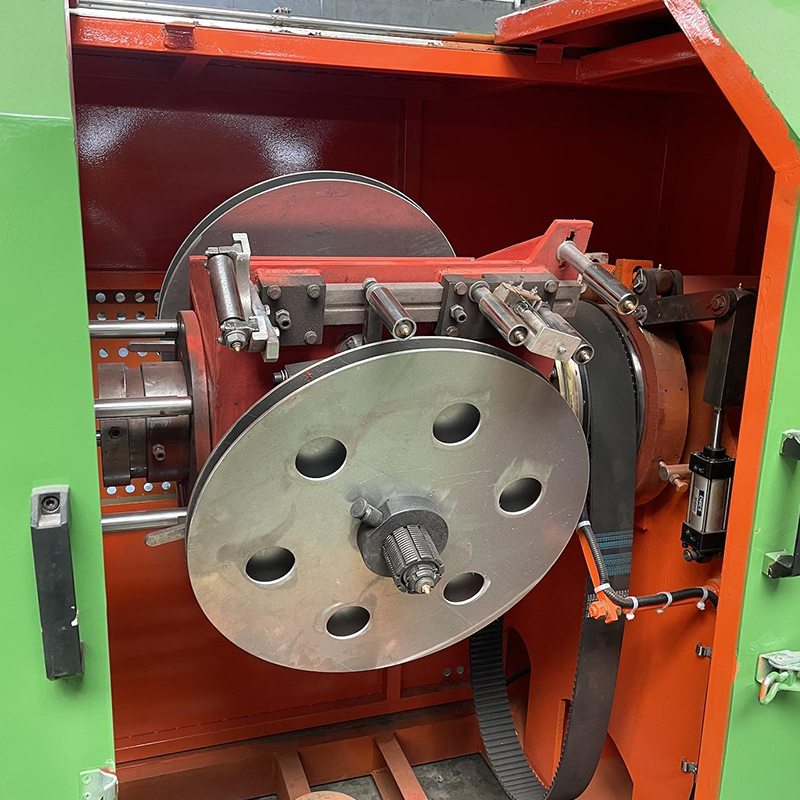

We believe in: Innovation is our soul and spirit. Quality is our life. Shopper need is our God for Rewinding/Winding Equipment, Rigid Copper Wire, Rod Drawing, Cable Winding And Shrinking Machine,Cable Winding Equipment. We warmly welcome customers from all over the world for any kind of cooperation with us to build a mutual benefit future. We are devoting ourselves wholeheartedly to offer customers the best service. The product will supply to all over the world, such as Europe, America, Australia,Durban, venezuela,Mali, Ecuador.We have now a good reputation for stable quality goods, well received by customers at home and abroad. Our company would be guided by the idea of "Standing in Domestic Markets, Walking into International Markets". We sincerely hope that we could do business with car manufacturers, auto part buyers and the majority of colleagues both at home and abroad. We expect sincere cooperation and common development!

Related Products